Voith’s Infinity +Green Press Felts Cut Carbon Footprint by 31% with Closed-Loop Recycling

Voith’s Infinity +Green press felts leverage ECONYL recycled polyamide and closed-loop recycling to slash Scope 3 emissions by 31% for EMEA papermakers.

voith.com

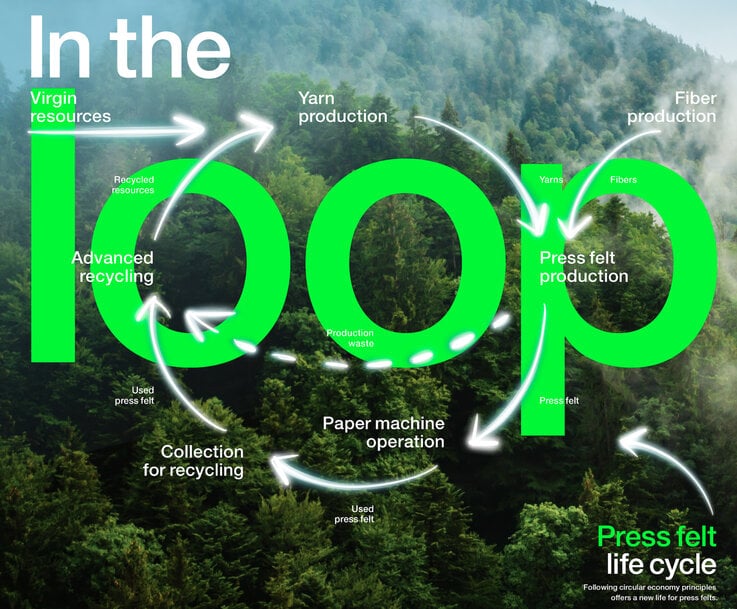

Voith is launching an innovative recycling concept for press felts in collaboration with its partner Aquafil, enabling papermakers to drastically reduce their specific product carbon footprint. The newly developed Infinity +Green press felts and a closed recycling loop reduce Scope 3 emissions by up to 31 percent.

“The majority of CO₂ emissions in press felt production are related to raw material sourcing,” explains Anne Klaschka, Global Product Manager Press Felts at Voith Paper. "In addition, around 20 percent is caused by end-of-life disposal. The focus on recycling solutions is a logical consequence of this and supports papermakers in achieving their ambitious sustainability goals. We have given ourselves the task of developing an innovative concept that meets both the requirements of the industry and environmental goals,” says Klaschka.

“Design for Recycling” concept

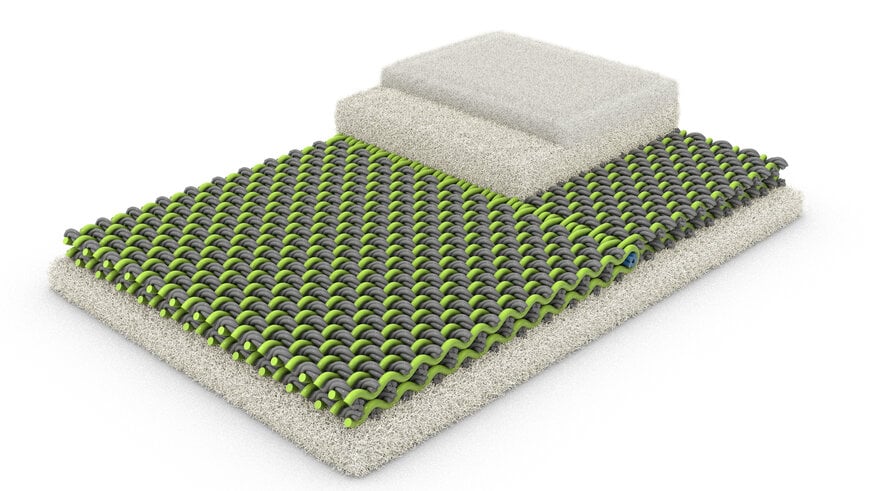

Voith's Infinity +Green press felts have been specially developed for recycling, with particular attention to the homogeneity of the product. Thanks to the implementation of the “Design for Recycling” concept, only one type of polyamide is used in the production of Infinity +Green. In order to meet the high-quality requirements of paper machine fabrics, Voith relies on chemical recycling through depolymerization. To this end, Voith works closely with Aquafil, a pioneer in PA 6 recycling. In this process, used PA 6 is converted into the monomer caprolactam, which is efficiently purified and repolymerized into high-quality PA 6 granulate under the brand name ECONYL. Depolymerization has proven to be less energy-intensive than other chemical recycling methods. In addition, this process preserves the original material quality, as unlike mechanical recycling, there is no loss of quality due to downcycling.

Reuse of resources in low-emission production

Voith uses recycled ECONYL granulate from Aquafil to produce new material for press felts at its own site, which perform exactly the same as felts made from new material. For felt production, Voith uses only green electricity, which is partly generated by the company's own hydropower plant. Thanks to the forward-looking design and sustainable production methods, papermakers using Infinity +Green benefit from a 15 percent reduction in Scope 3 emissions compared to conventional press felts.

Closed loop ensures a further 16 percent reduction in emissions

A closed recycling concept reduces the product's carbon footprint by a further 16 percent. “At Voith, we send our own production waste from felt manufacturing to our partner Aquafil,” says Anne Klaschka. In addition, we are setting up a recycling chain for our customers in EMEA for used Voith press felts." This way, used press felts from papermakers and unavoidable production waste are turned into new, high-performance press felts. “By combining Infinity +Green press felts with the recycling of used press felts, savings of up to 31 percent in the CO₂ footprint are already possible today,” highlights Klaschka.

The new Infinity +Green press felts are compatible with any machine configuration. Infinity +Green is already available everywhere in the EMEA region, with plans to expand global availability. With Infinity +Green press felts, Voith has achieved a breakthrough in the product-to-product recycling process. The latest advances underscore the leading full-line supplier's commitment to a sustainable future and its claim to support papermakers in achieving their ambitious sustainability goals.

www.voith.com