Voith Enhances Paper Production with Advanced NipMaster Analysis

Voith’s NipMaster software delivers data-driven shoe press optimization by refining dewatering efficiency, component alignment and overall press section performance.

voith.com

With NipMaster, Voith offers a powerful analysis tool that helps papermakers perform data-driven optimizations on the shoe press section of paper machines. The simulation-based evaluations specifically improve drainage, energy consumption and production performance – for greater efficiency, sustainability and quality in paper manufacturing.

Efficiency, sustainability and production flexibility are among the key success factors in the paper industry. The basis for advancing these goals is a precise design of the press section. In this context, Voith's NipcoFlex shoe presses have been impressing customers for decades with their reliable performance and robust design.

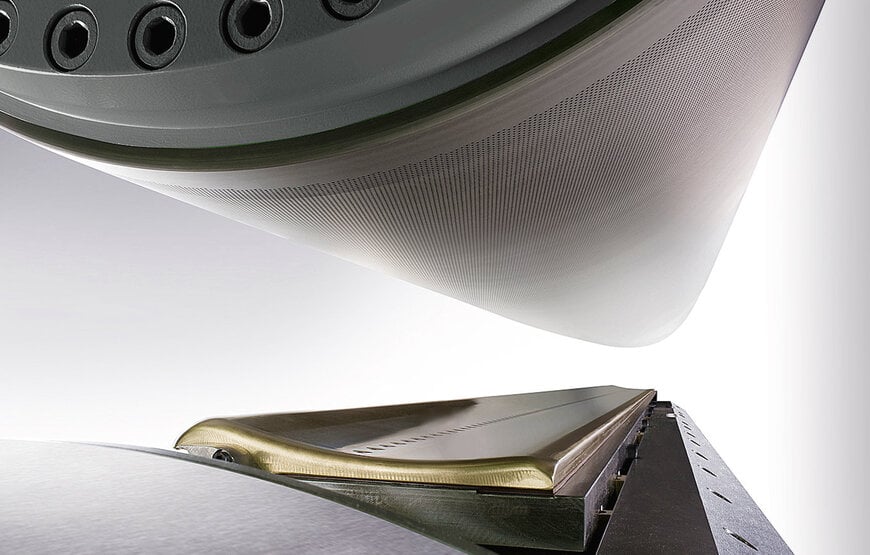

The main technological advantage of Voith's solution lies in the high press impulse, which is achieved through the interaction of a long dwell time in the nip and an optimized pressure gradient. Both parameters are crucial for maximum dewatering performance and consistently high paper quality. Optimal dewatering is the result of the precise interaction of a position-stable counter roll and a hydraulically pressed, concave pressure shoe – enclosed by a flexible press shell, such as the NipcoFlex sleeve from Voith.

Holistic view of the press section

However, the shoe press is only one part of the overall press section system. Experienced paper technologists know that the decisive factor is the complex interaction of all components. Only through careful coordination of the felt, shoe press belt, roll cover and doctoring can efficiency and productivity be significantly increased – and high paper quality guaranteed.

NipMaster: Data-supported analysis for optimum results

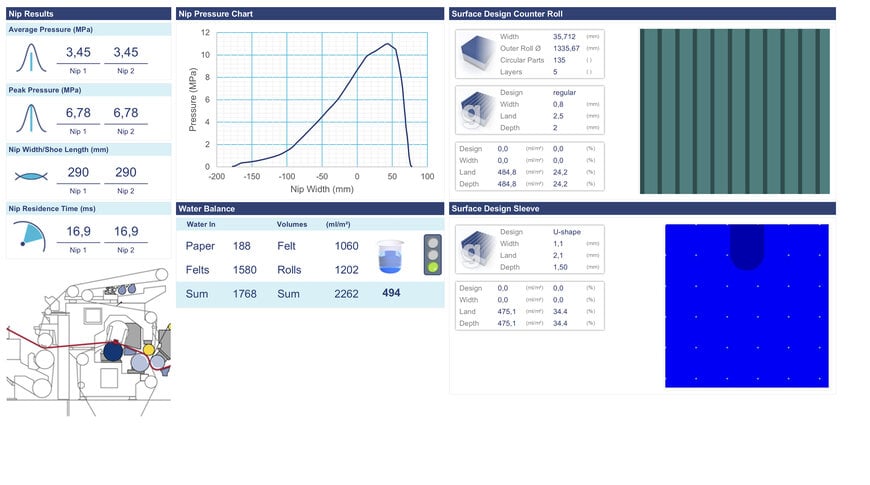

Many papermakers have therefore been relying on Voith’s NipMaster software tool for years. It enables data-supported analysis of shoe presses and combines the information obtained with state-of-the-art simulation technology, supplemented by decades of practical experience. NipMaster thus provides users with well-founded approaches for optimizing volume and dewatering concepts.

The tool factors in each machine’s specific configuration and supports adaptation to different grammages, among other variables. The results from NipMaster form the basis for optimizing the dry content and dewatering efficiency of the press section. With these insights, all components can be coordinated and optimized.

NipMaster thus provides all the relevant information needed to meet the diverse challenges in the press area in a practical and technologically sound manner. "With the NipMaster approach, we not only offer technological excellence but also create measurable added value for production targets," emphasizes Mario Neumann, Senior Application Manager at Voith. The optimization potential identified by NipMaster has a direct impact on production output and a lasting effect on operating costs.

Having proven its value, Voith has continued to invest in the further development of NipMaster for many years to make shoe press analyses even more precise and comprehensive – with the aim of significantly increasing the effectiveness and efficiency of the entire press section.

Analysis variety for a wide range of configurations

NipMaster analyses are tailored to every machine configuration – regardless of whether it is a Single, DuoCentri, Tandem or Triple NipcoFlex. The software tool considers the wide range of grammages that are commonplace, especially on board and packaging machines.

"Ranges from 70 to 220 g/m² are not uncommon," explains Neumann. The challenge here is that as the basis weight increases, the basis weight, initial dry content and machine speed typically change as well, resulting in variable requirements for the dewatering concepts. These must therefore be designed to be flexible and precise. NipMaster has already proven itself many times over as an indispensable tool for papermakers.

The software can be used to analyze numerous parameters, such as the current drainage situation, adjustment of the operating volume to specific pressure and water quantities, and optimal coordination of belt surfaces and felts for the respective drainage type, such as tube suction or lateral nip drainage. This holistic approach is essential, as excessive operating volume can have a negative impact on dewatering efficiency.

"Our goal is to precisely calculate and continuously optimize quality – from the surface of the shoe press belt to the counter roll," says Neumann.

Practical example Tandem NipcoFlex: fine tuning is crucial

The Tandem NipcoFlex provides a good example of how NipMaster works: For an optimal configuration, precise drainage distribution between the first and second nip is crucial. Typically, the drainage performance of the first nip is around 75 percent, with the second nip handling the remaining 25 percent. NipMaster analyses can be used to further improve the dewatering profile of the machine by adjusting the roll contact design, optimizing the belt surfaces and avoiding over- or undercapacities. "This level of fine-tuning is comparable to Formula 1 – here, too, the perfect coordination of the smallest parameters determines success," explains Neumann.

Conclusion:

With NipMaster, Voith bundles its comprehensive expertise in the press section. Changes to roll covers, felts or belts are always considered in the context of the entire system. This not only increases dry content, efficiency and runability, but also optimizes existing plants over the long term. It is therefore no surprise that shoe press analysis with NipMaster has established itself as the standard solution in the paper industry.

www.voith.com