www.magazine-industry-usa.com

20

'23

Written on Modified on

MIBA RELIES ON EMCO FOR RELIABLE AND COMPLETE PROCESS MACHINING OF PLAIN BEARING BUSHES

Turn-mill centre HYPERTURN 100 Powermill for complete machining of complex workpieces.

Sustainability in energy production

Wind power has become more socially relevant in recent years, and it contributes significantly to energy transition. However, wind farms need to become even more efficient in order to conserve resources. This is precisely where Miba Gleitlager Austria GmbH comes in with its hydrodynamic bearings for wind turbines. Miba uses a large number of HYPERTURN 100 Powermill turn-mill centres by Emco to machine the required plain bearing bushes.

Miba Gleitlager Austria GmbH, based in Laakirchen (Upper Austria), is one of the world’s leading manufacturers of engine bearings for large engines, compressors, and turbines. With the hydrodynamic bearings produced by Miba, significant performance enhancements can be gained compared to conventional rolling bearings. This technology has already established itself in many applications.

Miba bearings for wind energy

Wind power is a beacon of hope and source of clean energy. For more than five years, therefore, Laakirchen has also been working on bearing solutions for the gearbox in wind turbines. “Thanks to our comprehensive knowledge in the application of technology and materials, we can also offer customised and cost-effective bearing solutions for wind turbines beyond the limits of other bearing technologies," says Ing. Wolfgang Stadlmayr, Project Manager at Miba Gleitlager Austria GmbH, explaining the development step.

But wind turbines are also affected by the market economy (keyword: megawatt hour) and must therefore operate as efficiently as possible. This also increases the technological demands on wind turbines. And that is precisely what plays into Miba's hands: “Upcoming turbines will be designed for twice the production output. However, there’s no longer any need to increase installation space. Traditionally, used rolling bearings can hardly cope with these requirements, if at all," says Stadlmayr, explaining why more and more gear manufacturers worldwide rely on the specialist knowledge of the Upper Austrians; the plain bearings from Laakirchen are convincing with their very compact design, increased power density, higher load capacity, noise-reduced operation as well as simple assembly, lower maintenance requirements and increased service life.

High vertical range of manufacture ensures quality

“Due to the increasingly growing demand for energy, existing wind farms are being expanded and new ones built – particularly in China, but also worldwide. In order to be able to satisfy this high demand, we have massively increased our production capacities for wind bearing production,” continues the project manager, who is primarily responsible for machine selection and process development in the field of renewable energies.

The design of the HYPERTURN 100 Powermill with a powerful main and counter spindle, a B-axis with direct drive for complex 5-axis simultaneous machining and an additional lower turret system offers the possibility of complete machining of complex components.

Ing. Wolfgang Stadlmayr, Project Manager at Miba Gleitlager Austria GmbH

“Together with Emco, we were able to convert the manufacturing process for our Miba wind bearing bushes to process-reliable complete machining and thus significantly optimise it.”

Key components of the Miba Wind product portfolio are plain bearing bushes and thrust rings. The bushings are made from a composite material. “Our engine bearings are used in applications with diameters ranging from 125 to 500 mm and require great expertise in the manufacturing process.”

The plain bearing bushes are made of a composite material and are used in applications with diameters from 125 to 500 mm.

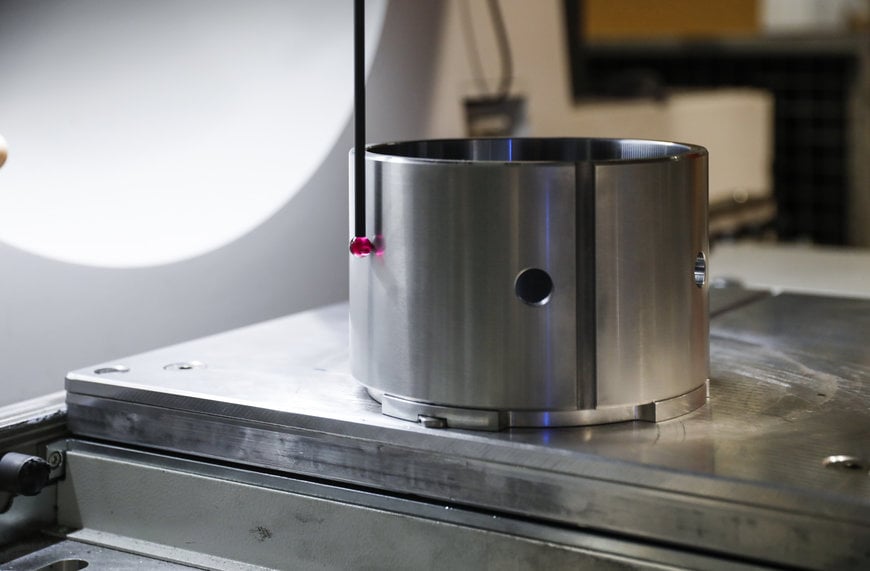

After complete machining, the quality is documented externally on a coordinate measuring machine.

Emco as a long-standing partner

Several HYPERTURN 100 Powermill turning-milling centres from Emco are in operation in Laakirchen to produce plain bearing bushes reliably and economically, as well as one in the production plant in China. “More are already on order so that we can cover the enormous demand on site, especially in Asia,” Stadlmayr reveals. The Upper Austrians have a long-standing partnership with Emco, as they invested in the first HYPERTURN series from Emco 20 years ago. “In total, Miba Laakirchen has already ordered 14 turning-milling centres from Emco, many of them partially or fully automated. And almost all of them are still in use," says Rupert Lehenauer, the responsible area sales manager at Emco GmbH. Miba deliberately does not award any turnkey projects but leaves the know-how in-house. “In this way, we always remain independent and can implement every project exactly according to our ideas,” explains Stadlmayr.

Rupert Lehenauer, Area Sales Manager at Emco GmbH

“Miba is a very important customer for Emco in terms of technology development. We are pleased to be able to contribute to sustainability in the field of energy generation.”

Flexibility required

This was also the case with the production design of the plain bearing bushes for the wind industry: “Basically, the project involved a certain risk for us, because we didn’t know for sure whether we would be able to manufacture the bushes with the necessary tolerances and surface qualities in a process-safe manner,” the project manager continues. That’s why Miba was looking for a partner who, in addition to the technical requirements, was as flexible as possible. Naturally, several potential machine manufacturers were contacted – in the end, Emco turned out to be the optimal partner for Miba once again: “On the one hand, we knew about the quality and reliability of the HYPERTURN series from many years of experience, and on the other hand, Emco agreed to implement the concept we had planned one-to-one and thus also to share the risk to a certain extent,” says Stadlmayr, explaining the decision in favour of the machine tool manufacturer from Hallein.

Miba designed the clamping device concept, which consists of standard and special clamping devices, internally. For the bushings to be machined as accurately as possible, the internal clamping is essential, among other things, so that the component is not deformed. “We had to take the specially designed clamping situation into account when planning of our HYPERTURN 100 Powermill and install it accordingly,” continues Lehenauer, who has been supporting Miba for more than 20 years, and who has also served as an interface to development and application technology in this special project.

Sophisticated complete machining

For machining, the unmachined part is inserted into the HYPERTURN by the machine operator. Both the outer and inner diameters are machined completely automatically on the main and counter spindles with the milling spindle and a lower tool turret. After complete machining, the finished components are measured externally on a coordinate measuring machine. “In this way, we can keep the specified tolerances in the micrometre range for the required diameters. For the wall thickness, we make a compromise between the necessary process reliability and the lowest possible weight,” Stadlmayr goes into detail.

Incidentally, before the project started, the entire process was simulated internally on a HYPERTURN 690 as realistically as possible before the project in order to obtain a certain degree of safety. Acceptance then took place at Emco in Italy, where around 30 components were manufactured and checked. “The first machining operations in Italy were satisfactory right from the start – all checks were positive, the process worked, and the specificities were given,” recalls Stadlmayr.

Optimum machine concept

Today, the manufacturing process runs around the clock – as already mentioned – on several identical HYPERTURN 100 Powermills. “The modular design with powerful main and counter spindle at a maximum spindle distance of 3,300 mm, a B-axis with direct drive for complex 5-axis simultaneous machining as well as an additional lower turret system offers the possibility of complete machining of complex components – like here at Miba – with a turning diameter of up to 500 mm,” Lehenauer points out the possibilities of the turn-mill centre from Emco.

The machine bed is of monobloc construction. This stable and compact construction as a travelling column principle is filled with polymer concrete, absorbs vibrations that can occur during machining correspondingly well and thus supports precision work on the workpiece. "All guideways are implemented with large-dimension, preloaded linear guides with glass scales. Rollers instead of balls further increase stability and damping while being more robust,” Lehenauer elaborates on other design features. Wolfgang Stadlmayr can only confirm this: “The HYPERTURN 100 Powermill provides us with the optimal prerequisite for the highest precision in the complete machining of our plain bearings.”

Successful cooperation: Miba has a long-standing partnership with Emco, having invested in the first HYPERTURN series from Emco 20 years ago. The picture shows Rupert Lehenauer (Emco, left) and Wolfgang Stadlmayr (Miba).

The machine base is of monobloc construction.

This stable and compact construction as a moving column principle is filled with polymer concrete, absorbs vibrations that can occur during machining well and thus supports precision work on the component. “All guideways are implemented with large-dimension and preloaded linear guides with glass scales. Rollers instead of balls further increase stability and damping while being more robust," Lehenauer elaborates on other design features. Wolfgang Stadlmayr can only agree with this: "The HYPERTURN 100 Powermill provides us with the optimal prerequisite for the highest precision in the complete machining of our plain bearings.”

Productivity significantly increased

By further developing the manufacturing process for wind bearings to include complete machining, Miba was able to significantly increase productivity. The tooling technology was designed by Miba together with a long-standing partner, and the processes were successively optimised and fully developed. “Currently, our machining time is already below what we’d expect. This all the more shows that the HYPERTURN is very powerful, but also stable and highly accurate,” concludes Wolfgang Stadlmayr, full of praise.

The Miba Group develops and produces mission critical components for applications along the entire energy value chain. This makes an important contribution to the efficient and sustainable generation, transmission, storage, and use of energy. The products – sintered components, engine and industrial bearings, friction materials, power electronic components and coatings – are in vehicles, trains, ships, aircraft globally, power plants, refineries, compressors, industrial pumps, and wind turbines. Founded in 1927, the technology group now employs around 7,400 people at 30 production sites worldwide and generates sales of around 971 million euros (financial year 2021/22).

Miba Gleitlager Austria GmbH

Dr. Mitterbauer Straße 3, A- 4663 Laakirchen

Tel.: +43 7613-2541-0

www.miba.com

TECHNICAL DATA HYPERTURN 100 POWERMILL

Workspace

Swing diameter over bed 800 mm (without tool turret)

Max. turning diameter 720 mm (with milling spindle)

Length between spindle and centre 1700 / 2400 / 3300 mm

X1 axis 780 (+760/-20) mm

Y-axis 420 mm

Z1 axis 1500 / 2200 / 3100 mm

Main spindle - counter spindle

Spindle connection (DIN 55026) A2-8" // A2-11"

Max. diameter power chuck 400 // 630 mm

Max. spindle speed (11" with gear) 3500 // 2500 rpm

Max. main spindle drive power 33 // 53 kW

Max. torque (11" with gearbox) 800 // 4400 Nm

Max. weight incl. chuck 350 // 700 kg

Max. weight between centres incl. chuck 800 // 1500 kg

Tailstock with quill MK 5

Travel (without steady rest) 1230 / 1930 / 2830 mm

Spindle sleeve travel 150 mm

Quill diameter 150 mm

Max. contact pressure 2500 - 22200 N

Tailstock traversing speed 15 m/min

X-, Z-, Y-axis

X1-X2-Z2 / Z1 and counter spindle 30 / 40 / 20 m/min

Feed force X1 / X2 1640 daN

Feed force Z1 / Z2 1640 daN

Counter spindle Z3 1640 daN

Milling spindle – Powermill

Speed range 0 - 12000 rpm

Max. torque 164 Nm

Max. drive power 52 kW

Tool holder HSK-T63/PSC63 (Capto C6)

B-axis

Travel range 240°

Holding torque of the clamp 6000 Nm

Drive torque interpolating 878 Nm

Driven tools (BMT 65P - VDI 40)

Speed range 6000 rpm

Torque 62 Nm

Drive power (max.) 22 kW

Driven tools (max.) 12

Tool magazine

Tool magazine positions 40 / 100 (200)

Max. tool length 500 mm

Max. tool diameter 90 mm

Max. turning tool weight 12 kg

Coolant device

Coolant pressure

(max. milling spindle / tool turret) 80 / 50 bar

Working chamber flushing 2 x 14 bar

Coolant tank capacity from 600 l

Power consumption (in relation to the desired machine version)

Connected load (max.) 117 KVA

Compressed air connection 6 bar

Dimensions (in relation to the desired machine version)

Height above corridor 1450 mm

Total length with chip conveyor 8100 / 8800 / 9600 mm

Height 3000 mm

Width / with control panel 3200 mm

Weight 25000 - 30000 - 35000 kg