www.magazine-industry-usa.com

30

'10

Written on Modified on

Brilliantly constant - Hysteresis capping heads for the beverage industry

Due to the constant, impact-free slip torque, hysteresis capping heads are better suited for sealing plastic bottles and non-returnable glass bottles than permanent magnet heads. The technically advanced ROBA®-capping head components by mayr® power transmission are based on the patented ROBA®-contitorque hysteresis clutch, which has been used in the market successfully in various applications for more than 10 years.

A characteristic feature of the permanent magnet heads traditionally still widely used today is the torque pulsation in slipping operation. During slipping, this torque pulsation causes alternating loads that are destructive to the attached components. The results are cost-intensive inspections, increased maintenance requirements and downtimes. For multi-way glass bottles, the use of these “hammering” heads is still considered appropriate.

When sealing plastic bottles, the ROBA®-capping head hysteresis capping heads with their constant, impact-free slip torque provide decisive advantages. The limit torque can be adjusted linearly quickly and easily. The set value can be read off directly. In this way, the closing torque, which is transmitted contactlessly and wear-free, can be optimally adjusted.

ROBA®-capping head hysteresis capping heads have a torque repetitive accuracy of +/- 2 % in constant ambient conditions. When comparing the bottle opening values, capping heads with hysteresis clutches do better than capping heads with permanent magnet clutches. The opening torque scattering is lower and the values are far more constant. Due to the constant, dynamic torque, the bearing load is very low. Furthermore, the wear on the sealing cone is minimised and the service lifetime can be increased.

Modular-design ROBA®-capping head components made of stainless steel can be maintained easily and problem-free by the user, who is able to carry out all necessary tasks themselves, from re-greasing the guides to replacing the bearing. No cost-intensive services to be carried out by the manufacturer are necessary. Due to the technical advantages, more and more new sealing systems are being equipped with hysteresis capping heads. Existing systems can also be retrofitted without any problems. Most permanent magnet heads can be replaced by hysteresis heads. Adaptors allow the necessary adjustments.

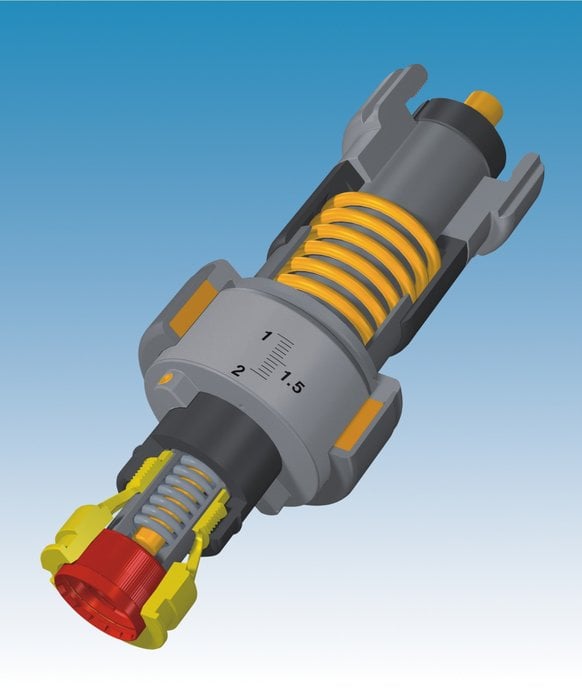

Fig. 1

File: F-2-04-Bild1.jpg

ROBA®-capping head Hysteresis capping head:

High-quality permanent magnets and magnetisable hysteresis material generate a highly constant, impact-free slip torque wear-free.

When sealing plastic bottles, the ROBA®-capping head hysteresis capping heads with their constant, impact-free slip torque provide decisive advantages. The limit torque can be adjusted linearly quickly and easily. The set value can be read off directly. In this way, the closing torque, which is transmitted contactlessly and wear-free, can be optimally adjusted.

ROBA®-capping head hysteresis capping heads have a torque repetitive accuracy of +/- 2 % in constant ambient conditions. When comparing the bottle opening values, capping heads with hysteresis clutches do better than capping heads with permanent magnet clutches. The opening torque scattering is lower and the values are far more constant. Due to the constant, dynamic torque, the bearing load is very low. Furthermore, the wear on the sealing cone is minimised and the service lifetime can be increased.

Modular-design ROBA®-capping head components made of stainless steel can be maintained easily and problem-free by the user, who is able to carry out all necessary tasks themselves, from re-greasing the guides to replacing the bearing. No cost-intensive services to be carried out by the manufacturer are necessary. Due to the technical advantages, more and more new sealing systems are being equipped with hysteresis capping heads. Existing systems can also be retrofitted without any problems. Most permanent magnet heads can be replaced by hysteresis heads. Adaptors allow the necessary adjustments.

Fig. 1

File: F-2-04-Bild1.jpg

ROBA®-capping head Hysteresis capping head:

High-quality permanent magnets and magnetisable hysteresis material generate a highly constant, impact-free slip torque wear-free.