EMCO Mecof Megamill: giant milling machine for power and precision

Customisable high-gantry EMCO solution with multi-head flexibility and full Industry 4.0 connectivity.

www.emco-bau.com

Off-scale dimensions, absolute control

Like all Mecof models, Megamill can be customised to meet customer requirements. The model currently on display at the Technology Centre in Belforte Monferrato (AL), built for a Chinese customer in the aerospace sector, is characterised by its impressive axis strokes: up to 42,500 mm in X, with a double crossbeam of 36,000 mm, 8,000 mm in Y for each slide carriage and 2,500 mm in Z for each of the slides. A structure designed to machine large components without compromising stability, rigidity and precision.

Everything is managed by the Siemens Sinumerik ONE numerical control, which ensures maximum reliability and a modern interface, ready to communicate with factory management systems.

Multi-head for every machining requirement

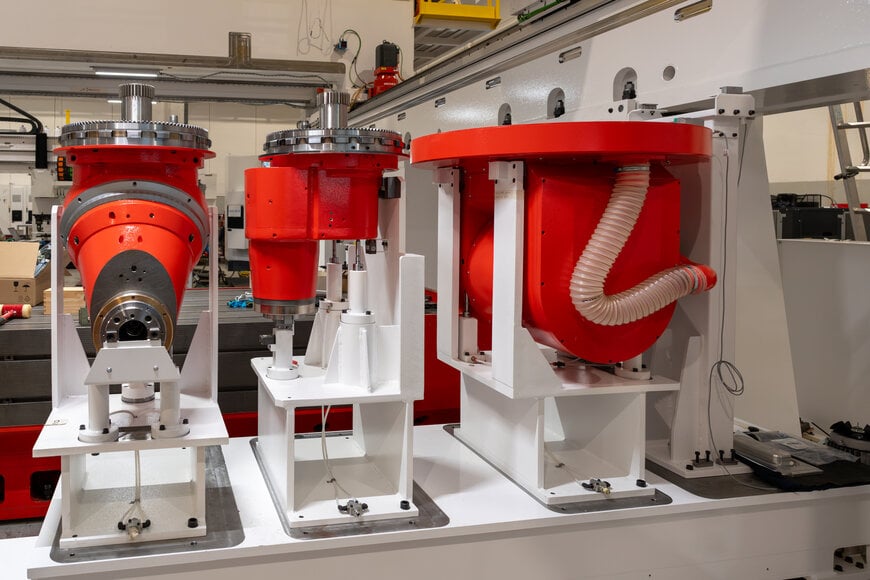

One of the strengths of the Megamill is its versatility in terms of milling heads, which make it a machine that is extremely adaptable to different industrial sectors. Specifically, the machine we are examininghas:

- Universal bi-rotary heads with millesimal positioning, 38 kW of power and up to 6000 rpm, perfect for high torque machining. ISO 50 tool attachment.

- Vertical head with offset spindle, ideal for heavy-duty machining, with 2000 Nm torque. ISO 50 tool attachment.

- Milling heads with torque motor and E55 electric spindle, capable of reaching 24,000 rpm and ensuring high-speed machining with HSK 63-A connection.

The package is completed by sliding head magazines, which allow quick and safe changes, and automatic tool changers with 48 positions each, consisting of two overlapping chains with 24 positions and a sliding stroke (tool connection: 28x ISO 50 and 20x HSK 63-A), for uninterrupted operational autonomy.

Automation and digitalisation

Mecof's Megamill is not only a powerful machine: it also guarantees Industry 4.0 connectivity for integrated process monitoring and management. In fact, the optional package with ‘Siemens Integrate Access My Machine OPC/UA’ allows direct connection to factory systems, facilitating real-time process monitoring. Added to this is the Siemens Omative Adaptive control and monitoring software, which dynamically adapts machining parameters, reducing cycle times and optimising tool wear.

Integrated precision and safety

Nothing is left to chance, especially when it comes to ensuring consistent quality and safety. Laser measuring systems and radio probes for tool and workpiece control, an anti-collision device between the crossbars and automatic top closure, in addition to guide pressurisation systems to protect the machine and keep the working environment clean, are all features of the model we are analysing.

Cooling and suction: designed for productivity

The dual-delivery cooling system (IRDD40) and 2000-litre filter tanks ensure continuity even during the heaviest machining operations.

On the environmental front, the Megamill is equipped with powerful extraction systems for composite materials such as glass fibre reinforced carbon fibre, both on the spindle side and on the flat side, ensuring a healthy and efficient working area.

The Megamill is not simply a high gantry milling machine: it is an advanced machining platform designed for those who need to tackle large-format production without compromise, with the certainty of being able to count on power, precision, automation and connectivity, reducing time and maximising productivity.

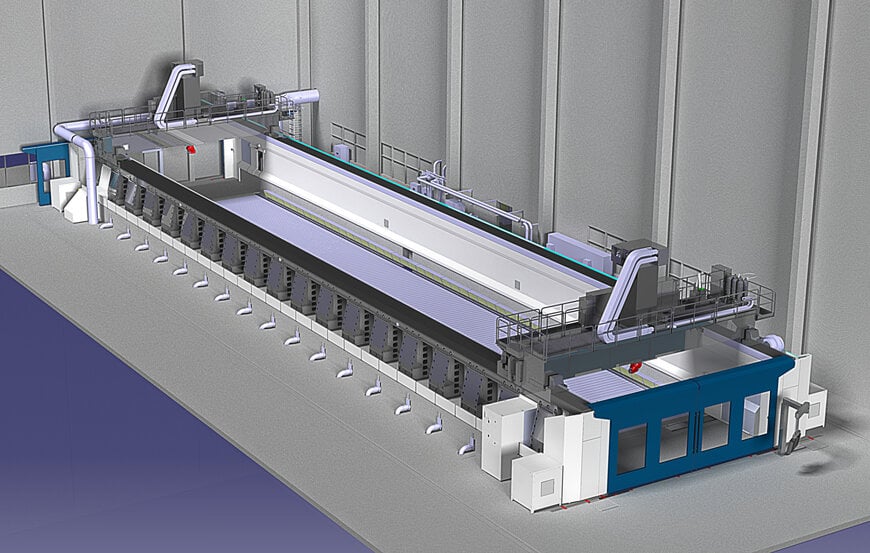

Rendering of the MEGAMILL exhibited at Mecof Open Days 2025

Impressive dimensions not only for 8,000 mm sledge carriages; in the photo we can see the 42,500mm of the total X stroke.

Milling heads supplied: from left, universal bi-rotary head, vertical head with offset spindle and fork head with suction system.

The Mecof Team proudly poses in front of the Megamill destined for China.

EQUIPMENT:

Megamill

CNC Siemens Sinumerik ONE

Full stroke in X 42.500 mm (X1/X2 = 36.000 mm)

Stroke in Y1/Y2 8.000 mm

Strokein Z1/Z2 2.500 mm

Number of HP5 platforms (C axis) 2

No. 2 universal bi-rotary head with automatic millesimal positioning 38 kW, 1000 N·m, 6000 rpm, ISO 50 tool connection

No. 1 head with offset vertical spindle, 38 kW, 2000 N·m, 3000 rpm, ISO 50 tool connection

2 milling heads (torque motors) with electric spindle, lubricated with ‘air/oil’ system, 42 kW 67 Nm in S1, 55 kW 87.5 Nm in S6, 24,000 rpm, HSK 63-A

3-position sliding magazine for housing the milling heads

2-position sliding magazine for housing the milling heads

Anti-collision device between the crossbars

Siemens package for Industry 4.0 consisting of ‘Siemens Integrate Access My Machine OPC/UA’, which allows automated connection of the machine to the factory logistics system, and CAPR (adaptive control option)

Secondary control panel on fixed column with video and duplicate controls

2 articulated arms for control panel

2 automatic 48-position tool changers, consisting of two overlapping 24-position chains with translational stroke. Tool attachment, 28x ISO 50 and 20x HSK 63-A.

2 Siemens wireless remote control panels, model HBG 800-DP

4 radio measurement probes (2 for ISO 50 connection and 2 for HSK 63-A connection)

2 laser devices for measuring tool length and diameter, permanently installed on the X-axis structure near the tool changer, including the control tool for each spindle

4 X, Y and Z axis guide pressurisation systems

Closure of the upper part of the automatic machine

2 dual-delivery cooling systems: 1) delivery near the spindle (pressure 6 bar, flow rate 28 l/min) via manifolds and rigid adjustable nozzles; 2) supply through the spindle (pressure 40 bar, flow rate 20l/min) via a hole coaxial with the spindle for use with tool holders with a central hole (tools according to DIN 69871/A)

No. 2 2000 l filter tanks

No. 2 2000 l collection tanks

2 dust extraction points on the spindle nose, including two-position extraction cap mounted on milling heads with a flow rate of 1,500 m³/h, head of 5,500 Pa and power of 5.5 kW

Suction system on the side of the work surface with a flow rate of 8,000 to 12,000 m³/h, suction capacity of 370 mm H₂O and power of 15 kW

No. 2 extended stop and retraction

No. 2 SIEMENS OMATIVE Adaptive control and monitoring software option