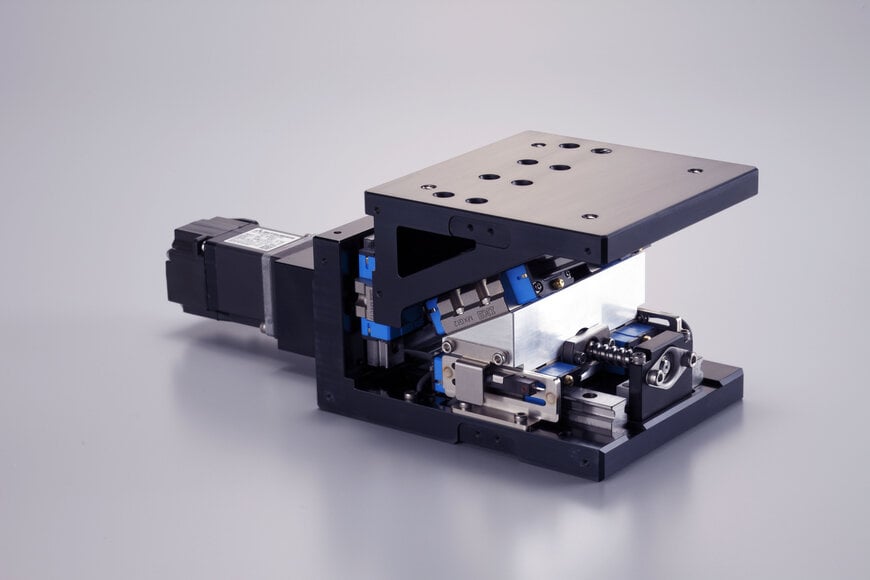

New IKO Elevating Tables Provide Precise Vertical Positioning in Tight Spaces

Compact wedge-driven design with integrated sensors and optional encoder delivers ±0.001 mm repeatability for high-precision manufacturing.

The elevating table features a unique wedge mechanism guided in the vertical direction by a pair of IKO C-Lube Super MX linear motion rolling guides arranged in parallel to achieve highly precise positioning with exceptional rigidity. An optional linear encoder provides full closed loop control to achieve positioning accuracy as high as 0.005 millimeter, with repeatability of ±0.001 millimeter. Limit, origin and pre-origin sensors are integrated into the standard version to save space and simplify mounting.

The integrated Super MX linear motion rolling guides come with built-in IKO C-Lube capillary systems, supplying lubricating oil to allow maintenance-free operation for five years or 20,000 kilometers.

Additional features and specs include:

- A choice of two table dimensions: 120 and 200 square millimeters.

- Wedge reduction ratios of 1:2 and 1:4 to allow an ideal stroke length and resolution for the application.

- Vertical stroke of up to 24 millimeters.

- Precision ball screw drive.

- Durable aluminum construction.

For applications requiring XYZ-axis positioning, TZ elevating tables can be combined with an IKO CT Series positioning table.

For more information about IKO TZ Series elevating tables, please visit www.ikont.com.