Conveying the benefits of air amplifiers

.

www.smcusa.com

Air conveyors (sometimes known as pneumatic conveyors) have the potential to operate in two modes, offering vacuum (negative) and pressure (positive) conveying. Vacuum conveying uses compressed air to ‘suck’ bulk material like grains or pellets through a closed system of pipes. In contrast, pressure conveying (achieved by reversing the air flow) ‘pushes’ bulk material through the pipeline. The optimal technology supporting this capability is an air amplifier and, with its recently introduced ZHV series, SMC has a powerful performer.

Air conveyors are popular for moving dry bulk materials like powders, granules, or pellets between different locations, such as from a truck to a silo. Product examples extend from cement, flour, and sugar to pharmaceuticals and cosmetics. However, every material is different. Understanding the requirements of the specific material that needs conveying will help safeguard product quality and process efficiency.

The optimal way to create a flexible process suitable for different products is to ensure the system can perform both vacuum and pressure conveying. Vacuum conveying has certain advantages in that there is no contact between the compressed air and the material in transport, ensuring zero contamination. Furthermore, the product suffers no exposure to heat generated in the air compression process. However, the distance that can be covered with this method is limited. For longer pipelines, pressure conveying typically becomes the preferable option.

Go with the flow

Historically, air conveyors use either a compressor or blower to achieve the necessary high suction (vacuum) or discharge (blow) flow rates, but these come at the cost of high compressed air consumption.

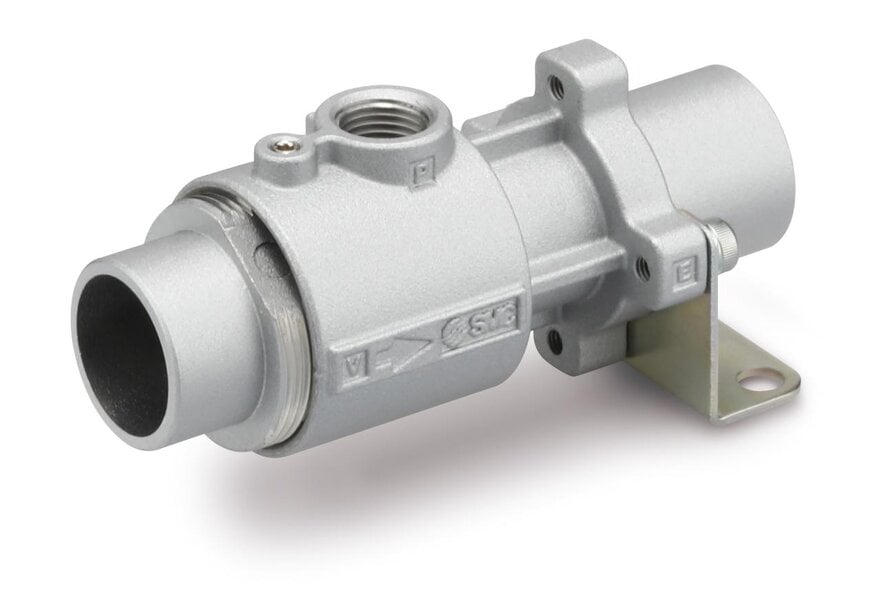

Today, a better approach is possible by introducing the SMC ZHV energy-efficient, compact and lightweight air amplifier, which can function as either a blow-off or vacuum unit depending on the direction of the output port. The ZHV uses the Coandă effect to amplify the supply flow rate, driving cost savings through an efficient solution that lacks nothing in performance: the blow air flow generated is four times the air supply (up to 11,000 l/min ANR), while the vacuum air flow generated is three times the air supply (up to 8,000 l/min ANR).

Notably, the flow rate is fully adjustable simply by altering the nozzle position in accordance with the specific requirements of the air conveying process. Turning the nozzle clockwise increases the flow, subsequently elevating the vacuum pressure or discharge flow rate (depending on mode of use). Similarly, turning the nozzle anti-clockwise decreases the flow, which has the effect of reducing the vacuum pressure or discharge flow rate.

Blow air consumption away

Air amplifiers are not expensive devices. SMC has already seen projects that generated a return on investment (ROI) in less than eight months thanks to annual savings in air consumption.

While the output pressure of an air amplifier is less than a common air nozzle, the volume of air is higher to deliver a similar outcome. Importantly, an air amplifier needs less input pressure to achieve the same air flow, permitting users to reduce system pressure and enjoy the associated savings in energy consumption and carbon emissions. Use cases show that it is possible to save up to 70% in air consumption without any compromise in results.

The ZHV, which is the successor to SMC’s previous ZH-X185 (and is completely interchangeable), outperforms alternative products from other suppliers by around 20%.

Size matters

Changes from the previous-generation product include a far more compact and lightweight design, making it ideal for machine builders and manufacturing plants under pressure to reduce machine size. The optimised profile of the SMC ZHV offers a reduction in internal volume of up to 50%, depending on the model selected, while weight is up to 50% less. ZHV series air amplifiers also retain many advantages of the ZH-X185, such as a large passage diameter to suit several other potential applications, like collecting chips and swarf during the machining of metal or resin workpieces.

The easy-to-install ZHV is air driven (no electricity required) with only one supply port, while the absence of moving parts makes for maintenance-free operations. To ensure optimal selection in line with the requirements of the specific air conveyor, always seek the advice of an SMC specialist.

More info: https://www.smcusa.com/products/zhv-vacuum-flow~172972

Contact: This email address is being protected from spambots. You need JavaScript enabled to view it.