The right solutions for all intralogistics needs LogiMAT 2024 with Bonfiglioli

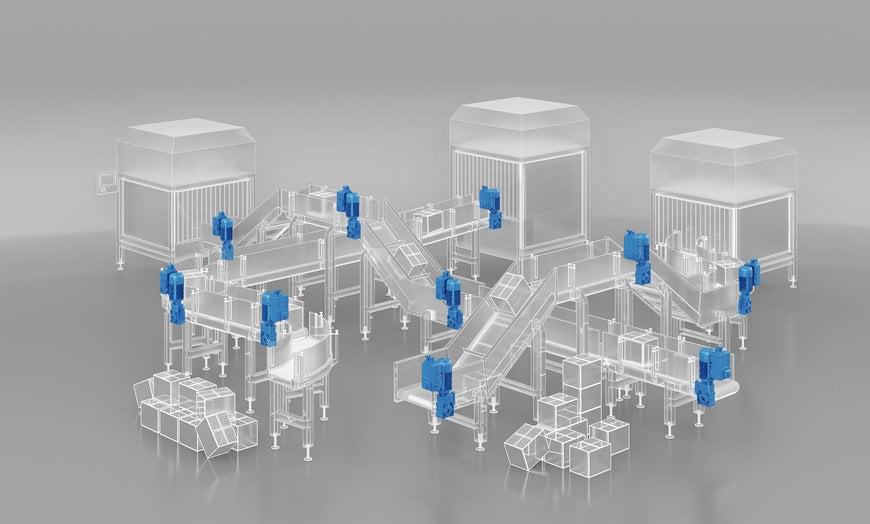

Bonfiglioli boosts its participation at LogiMAT with two booths: the first, in the Hall 10, is dedicated to Solutions for Mobile Intralogistics (Booth 10D13), the second, in the Hall 7, is focused on Logistics Automation Solutions (Booth 7F09).

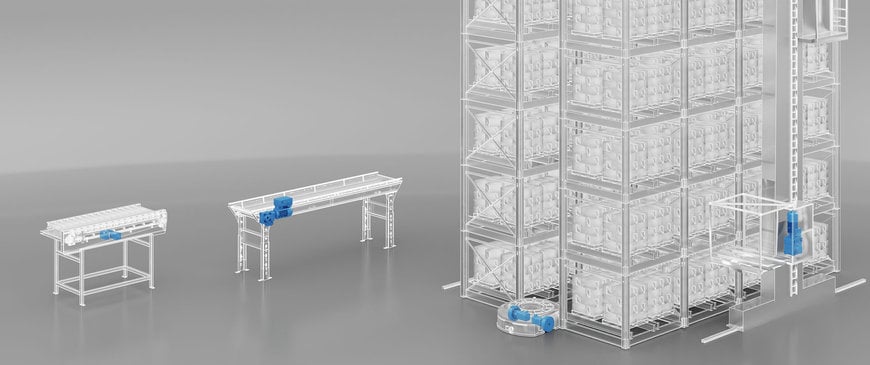

This double presence holds significant strategic importance, reflecting the company's steadfast commitment in the development of complete cutting-edge solutions for warehouse operations, under the sign of efficiency and sustainability. Showcased is a wide array of systems for belt and roller conveyors, AGVs, AMRs, forklifts and automatic storage systems, as well as an IoT platform.

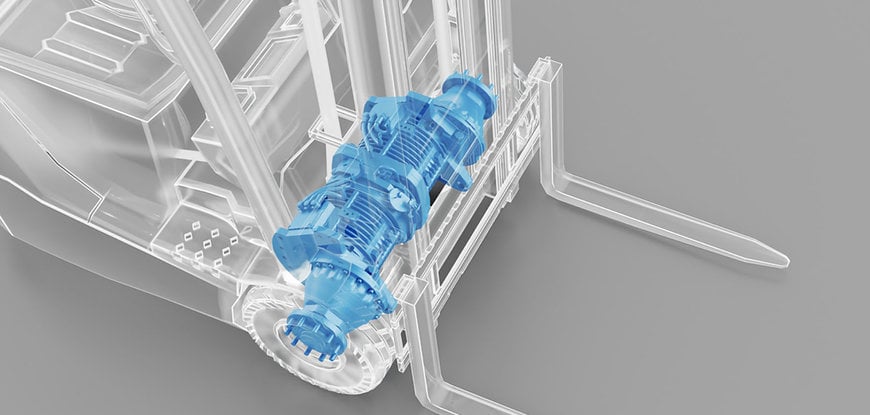

In the Hall 10, Bonfiglioli dedicates ample space to the 600F series, electric drive axles for forklifts, which makes a significant return. The series is equipped with planetary axles and drives featuring integrated high-performance electric motors and low-maintenance braking systems, and it can be applied to 3- and 4-wheel counterbalance lift trucks and ground support equipment. These drives are available in different sizes, also for bigger forklifts, and offer reduced energy consumption, resulting in longer battery operating times, extended service intervals and a lower overall cost of ownership.

The EL Series which identifies steerable powertrains for pallet trucks, stackers, reach trucks and other types of warehousing machinery, has been expanded this year into the new size EL 16. Developed for heavy load warehouse equipment, it is equipped with a multifunction unit that ensures the complete control of acceleration, steering and braking. It can carry a vertical load up to 4.5 tons and thus represents the best choice for the most demanding warehousing applications.

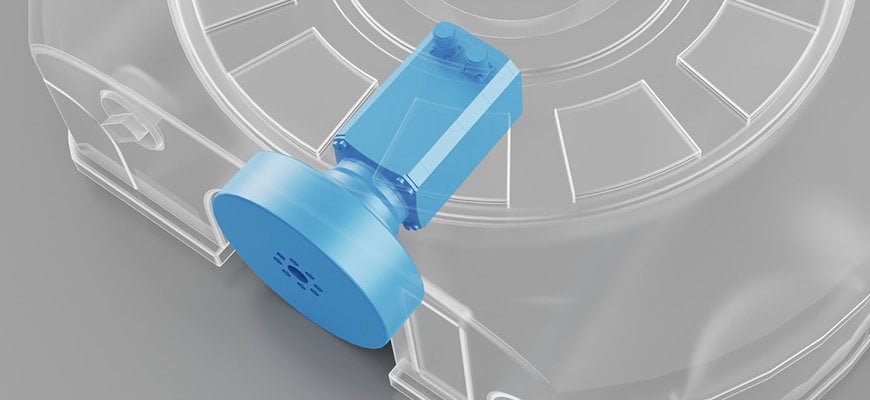

BlueRoll is also on display. This innovative platform features wheel-mounted gearmotors tailored for AGVs and AMRs, boasting an ultra-compact and energy-efficient design to ensure prolonged operational cycles. The modular drive system offers three configurations - Basic, Advanced, and Compact - with customizable single gearbox loads ranging from 360 to 1020 kg and a maximum speed of 2m/s.

In the Hall 7, Bonfiglioli unveils three solutions that improve efficiency, boost productivity and reduce downtime. An AGV solution featuring the platform BlueRoll is also present at this booth.

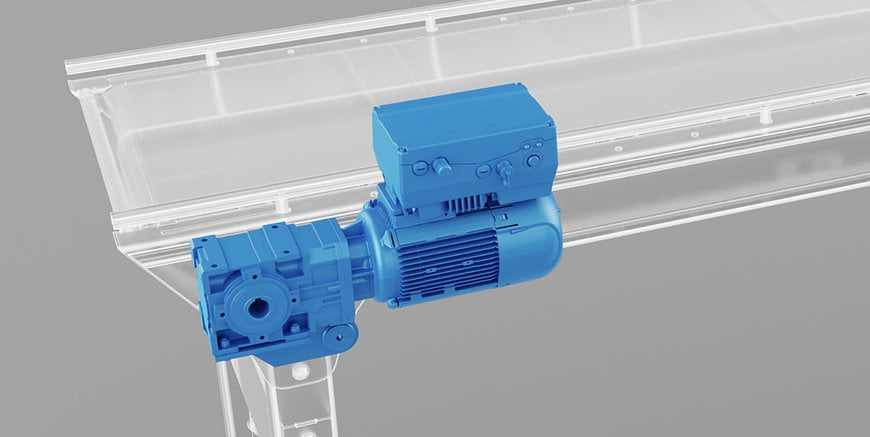

The first intralogistics solution showcased at the Booth 7F09 and which has been specifically developed for post & parcel handling systems, combines high efficiency and reliability, low maintenance costs and a wide torque range. It consists of a compact right-angle A gear unit available in a wide torque range, an IE4 certified reluctance synchronous motor of the BSR series - an ecological and high-performance product (thanks to the absence of magnets) - and a DGM decentralized inverter, fitted with a sensorless vector operation for an optimal dynamic control.

The right angle layout between INPUT and OUTPUT makes the A Series particularly compact. The gear set combination makes this right-angle product the most efficient and durable in Bonfiglioli's light and medium-duty portfolio. The A Series can be completed with a wide range of electric motors entirely manufactured by Bonfiglioli.

For heavier applications, i.e. logistics and transport on roller conveyors carrying out bulky parcels and pallets, Bonfiglioli has developed the second combined solution featuring a helical in-line CP47 gearbox, a MXN 20 asynchronous reluctance motor and a DGM decentralized inverter. Indeed, DGM inverters offer many benefits in terms of efficiency, reliability and safety, because wiring and troubleshooting costs are reduced, while product modularity and interchangeability are enhanced. Moreover, real time check of main gearmotor parameters is guaranteed through fieldbus interfaces or protocols.

The third solution boasts a BMD servomotor – a permanent magnet synchronous motor with highly compact dimensions and low inertia - combined with an A20 helical bevel gearmotor and the inverter AxiaVert. Top-level functional safety and high control performance for a wide spectrum of applications are the key benefits and features of the AxiaVert platform. A drive which offers seamless integration into automation networks and compatibility across an extensive range of fieldbus protocols, both on a serial and on an Ethernet basis, fostering production optimization in accordance to Industry 4.0 standards.

Its different Functional safety variants allow to optimize configuration, reducing the need for external safety components and ensuring a safe and controlled operation to minimize hazards. Additionally, precise motion control for open and closed loop applications maximizes efficiency and productivity, for a wide range of motion requirements. Its modular structure allows flexible adaptation to diverse applications by selecting appropriate hardware modules and customizing operational behavior through user-level PLC software programmability.

Available in different selectable cost and performance related variants – Basic, Standard and Motion: the latter including the networked safety protocol FsoE (Fail Safe over EtherCAT). AxiaManager is the comprehensive engineering software designed for the planning, commissioning, operation, and monitoring of the AxiaVert inverter series. Furthermore, Users can count on support from a Bonfiglioli expertfrom commissioning to troubleshooting thanks to an online remote assistance function.

Finally, Bonfiglioli presents its Condition Monitoring and Predictive Maintenance services, which respond to the necessity of maintaining comprehensive control and visibility over machinery. The former allows customers to know the overall status of their equipment by regularly collecting real-time data and identifying significant changes in parameters through an IoT platform equipped with sensors that measure performance, consumption and real duty cycle of the machine. The latter helps prevent damages and downtime by providing key information about, for instance, oil change intervals and hence planning the necessary technical operations in advance.

www.bonfiglioli.com