www.magazine-industry-usa.com

19

'23

Written on Modified on

hyperMILL® TURNING Solutions at EMO 2023

Mill turning: OPEN MIND boosts efficiency and process reliability.

hyperMILL® TURNING Solutions are the hot topic for OPEN MIND at this year’s EMO. Live demonstrations on a GROB G350T mill-turn machine will be performed at the booth to display what the milling-turning technologies of the hyperMILL® CAD/CAM solution can do. The demos will also include milling, drilling and angle head support.

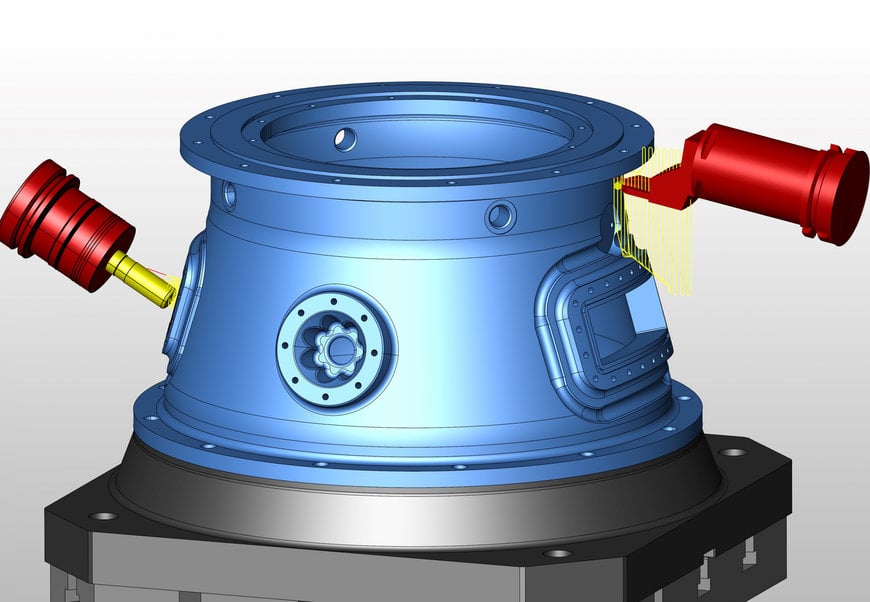

hyperMILL® TURNING Solutions include technologies for turning, turn-milling, and mill-turning, meaning they can be used for all corresponding machine configurations. OPEN MIND has chosen a housing component made using high-strength EN AW 7075 aluminum to demonstrate the capabilities of hyperMILL® in practice. The component is 372mm in diameter and 200mm high and engages in turning operations on the outer and inner contours. It also features various milled geometries inspired by typical requirements in different industries. These include housing elements from plant engineering for the semiconductor industry, surfaces such as those used in mold making, as well as reverse counterboring and angular head support functions – demonstrated live for the first time – which is in particular demand in mechanical engineering.

Trochoidal roughing and simultaneous machining – the high-performance turning strategies of hyperMILL® TURNING Solutions are fast and tool-friendly at the same time.

Tool-friendly turning

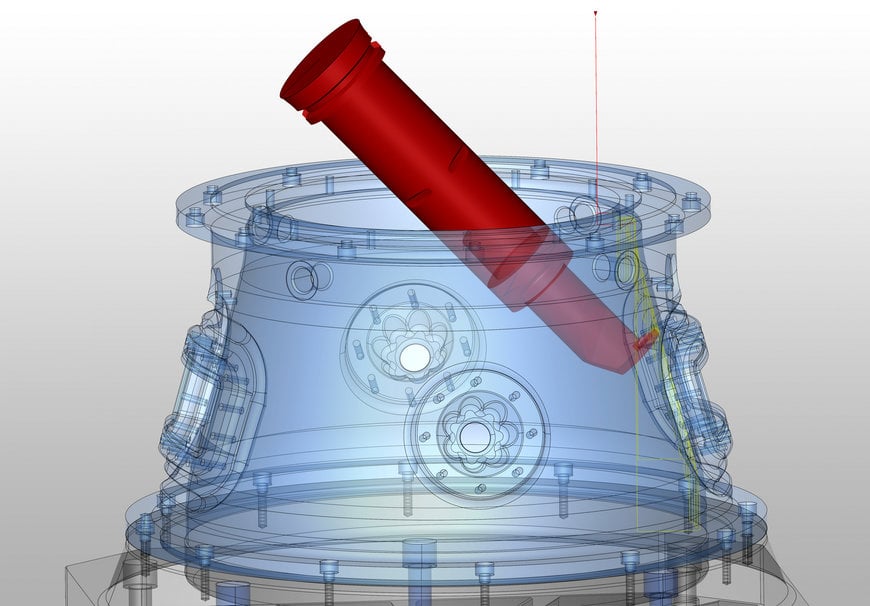

When roughing and finishing the external and internal contours, the benefit of simultaneous machining is impressively demonstrated alongside standard machining. Two areas that would otherwise have to be finished individually can be machined in one step with simultaneous turning and without a visible edge. Among the high-performance strategies shown will be trochoidal roughing. A high material removal rate is achieved quickly and gently without any major lifting movements.

The advantage of 3-axis simultaneous turning is also clear from the undercuts when machining the inner contour. Without this technique, these areas would be difficult to manufacture. Trade show visitors can see how easy it is to program 3-axis simultaneous turning. For even better performance, simultaneous roughing can also be used with the HPC option.

Without 3-axis simultaneous turning, undercuts like these wouldn’t be possible.

Milling rates

The live machining demonstration at EMO contains an example of a 5-axis halfpipe with finishing operations. OPEN MIND shows how quickly optimized tool paths can be programmed for grooves and tubes that produce the highest quality surface finishes. Perfect surfaces are also shown in another geometry. To minimize the effort required for grinding and polishing steps, hyperMILL® offers a machining strategy with gentle overlapping, creating perfect transitions that are barely measurable.

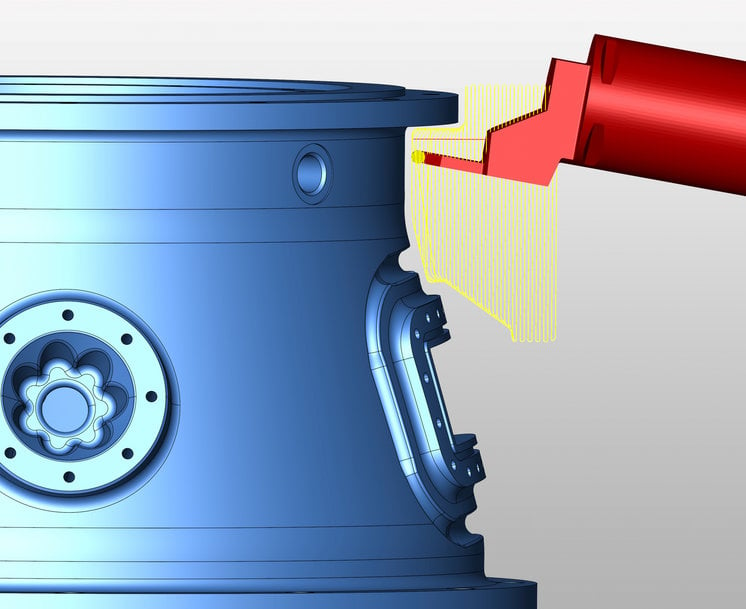

Secure programming

As an example of the safe programming of machining operations with a high risk of collision, a reverse counterboring task has been integrated into the demonstration, i.e. the control of a tool for deburring and milling cylinder countersinks on the inaccessible rear side of a bore.

www.openmind-tech.com