www.magazine-industry-usa.com

03

'15

Written on Modified on

Dorner’s New 2200 Series Precision Move Pallet System Conveyor are Perfect for the Assembly Automation Market

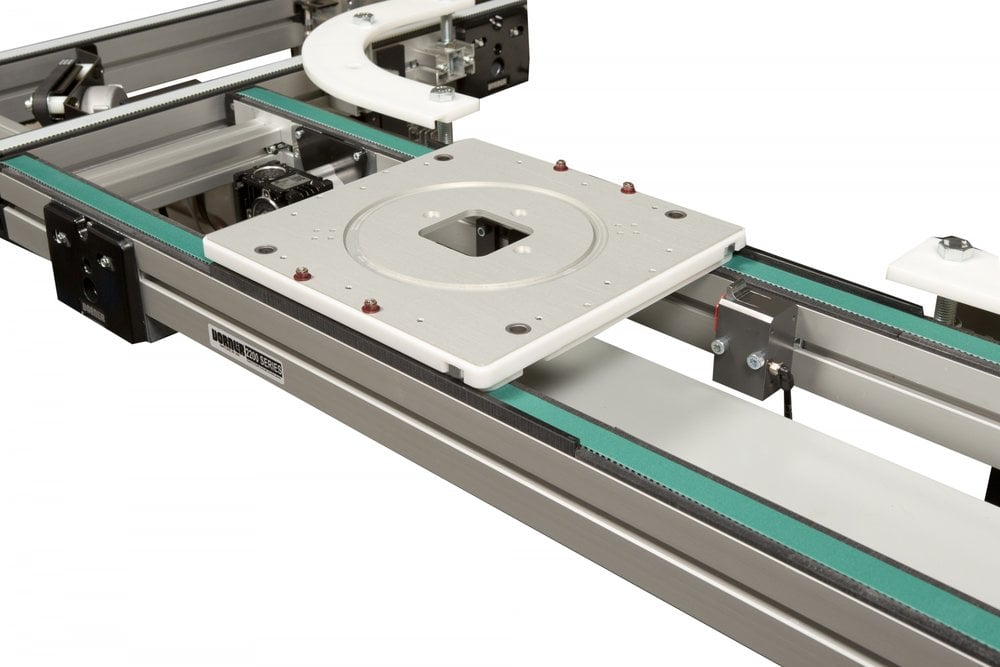

Dorner Mfg. continues its push into the assembly automation market with the debut of its new 2200 Series Precision Move Pallet System conveyor.

The pallets on this conveyor range from 160 mm to 480 mm, giving the customer the flexibility to select the proper size to move the product. During operation, pallets move on twin dual strand timing-belt conveyors. This design provides many benefits to end users, including ddded load capacity in a small platform (up to 250 lbs accumulated), quick belt change without the need to remove conveyor from system, widths (160, 240, 320, 400 and 480 mm), lengths up to 7,500 mm, 20 days or less delivery time, clean room class 100 Certification on the conveyor.

These engineering designs position the 2200 Series Precision Move Pallet conveyor as the go-to platform for applications in machine integration, robotic pick-n-place, precision indexing, accurate part positioning, timed conveying, and inspection.

Performance specifications of the 2200 Series Precision Move Pallet conveyor include:

Lifting Modules

- Lift and Locate: djustable height lift from center of conveyor, provides 200 lbs of lift capability at 90 psi, accuracy of +/- 0.002”

- Lift and Rotate: pneumatic lift from center of conveyor, pneumatic rotation with adjustable positioning, rotation angle (90 to 180 degrees adjustable), includes cushioned lift stroke

- Lift and Transfer: changes product orientation, uses dual strand timing belt conveyors and pneumatic lift, 70 lbs load capacity

Simple Powered Corner Modules

- 90 Degree Corner: uses pin tracking in pallet, maintains product orientation through the turn, includes 24 VDC drive mechanism to drive the pallet around the corner

- 90 Degree Corner and Merge: uses pin tracking in pallet, inside guide is mounted to pneumatic cylinders to transfer pallet around corner, straight guide with pneumatic cylinder is mounted across perpendicular conveyor to guide pallets straight through the merge area, includes 24 VDC drive mechanism to drive the pallet around the corner

Pin Tracking System

Simple and cost-effective method of tracking pallets through the turns

Used on 90 degree corner and 90 degree corner and merge modules

For more information on the 2200 Series Precision Move Pallet System conveyor, visit www.dornerconveyors.com.