www.magazine-industry-usa.com

29

'22

Written on Modified on

Phonenix Labeling: AUTOMATION AS A SOLUTION TO THE LABOR SHORTAGE

Finding enough workers to fill open positions is proving to be a historically difficult task for US businesses of all sizes and in nearly every state. According to the most recent statistics, there are currently over 10 million job opportunities in the United States, but only about 6 million unemployed people.

Although it is expected that this historical labor shortage will persist in the coming years, many US businesses are looking for ways to operate with fewer employees wherever it is possible.

The labor shortage has a major impact on several industries, including Fulfillment and Distribution centers.

The demand for warehouse workers is increasing since the recent explosion of the E-commerce sector.

Automation that might have seemed out of budgetary reach is now justifiable, so manufacturing plant managers are deploying it more often than in years past.

SLAM AUTOMATION

If you look for increased sustainability and operational efficiency, the final 100 feet of fulfillment operations are one of the best parts of a distribution facility to focus on. This is the area where Scanning, Labeling, Application, and Manifesting takes place.

Especially in large enterprises where the efficiency is exponential, automating SLAM activities can provide a nearly instantaneous return on investment (ROI).

You can explain SLAM automation in simple terms: instead of having an employee scanning labels, you can place a scanner on the line; instead of having a person printing labels and sticking them on cartons, you can use an automatic Print & Apply labeling system.

Automating SLAM can reduce costs and save time, as well as improve employee retention. When operators can lighten up on their tasks and allow machinery to take over parts of it, they have the opportunity to perform other job functions, which allows them to enjoy their work more. In the middle of a labor shortage, this is critical.

Other benefits to automating SLAM include a reduction in errors as the jobs are taken out of the hands of humans. Fewer touch points mean less opportunity for things to go wrong, and customer gains an increase in productivity.

SMART ALL-ELECTRIC PRINT & APPLY

Print & Apply labeling systems are the core of every SLAM area.

By automating the last 100 feet with smart labeling technologies, you improve your accuracy rates— shipping errors are expensive—and your ability to provide more throughput grows dramatically.

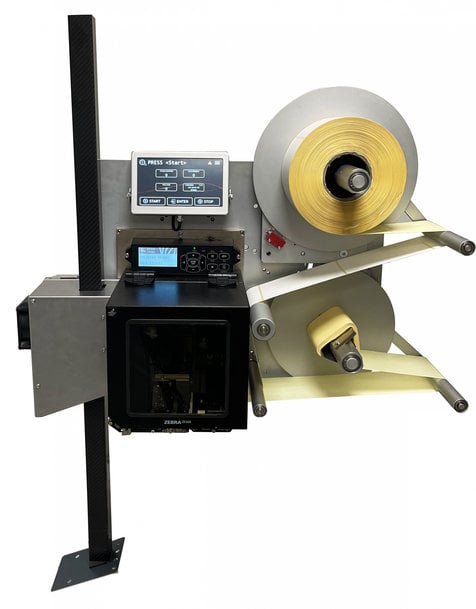

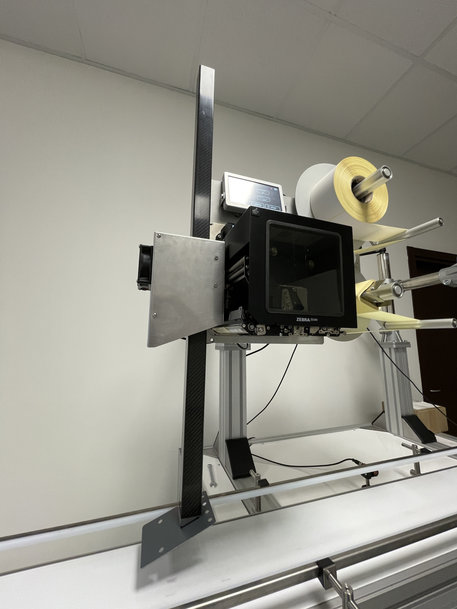

Phoenix Labeling is excited to announce the launch of a new revolutionary Print & Apply system specifically designed for SLAM integration.

This new full-electric solution is built around a light yet robust linear applicator made of carbon fibers.

A powerful stepper motor allows great performance, while guaranteeing the maximum safety for the operators: the low torque of stepper motors and the total absence of pinching points, make this new solution the safest Print & Apply system of the market.

With a maximum stroke of 770 mm, the new SLAM applicator is the perfect solution to dynamically apply identification labels on packages with different heights: a smart laser sensor detects in advance the height of the incoming package and instructs the full-electric applicator about the correct labeling height position.

A Wipe-On flexible label pad gently apply the label on the top surface of the product, without the need to use compressed air for the vacuum/blow processes.