www.magazine-industry-usa.com

05

'14

Written on Modified on

2014: DIRIS Digiware sparks a revolution in electrical measurement

Twenty years after shaking up the electrical measurement market with the DIRIS system, the first multi-measurement solution, SOCOMEC is once again leading the way with its latest technological innovation: DIRIS Digiware, a totally modular and flexible energy measurement and monitoring system

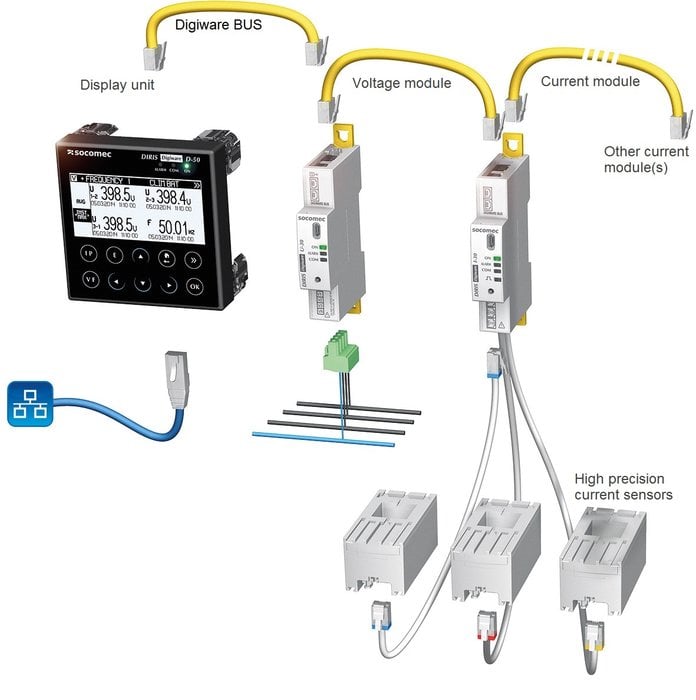

The system comprises as a minimum a display unit, a voltage measurement module, multiple current measurement modules and current sensors.

More precisely, the DIRIS Digiware modular system is based on a centralised display and a single voltage measuring point for the entire system. DIRIS Digiware offers an effective function-sharing capability. It also includes current measurement modules that are interconnected via the Digiware bus (RJ45 cables) for measuring energy consumption at the closest point to the actual loads. Each module can monitor one or more circuits via the current sensors by means of independent current inputs (3, 4 or 6 depending on the modules). With 3 inputs, a current module can monitor a three-phase circuit or 3 single-phase circuits.

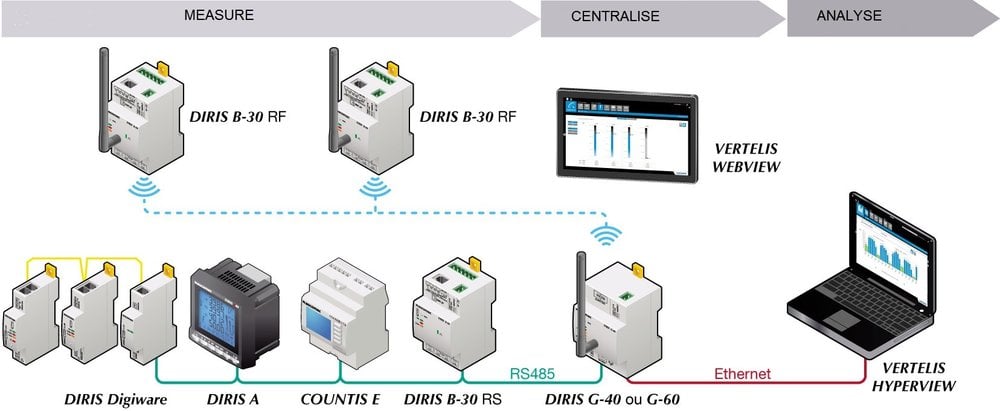

These four elements (centralised display, voltage measuring point, current measurement modules, current sensors) constitute the heart of the system. For applications without local display, the DIRIS Digiware C-31 system interface centralises all of the system’s data. The data from the Digiware modules and remote units is centralised on one or more DIRIS G communication gateways. Each gateway includes a WEBVIEW web server for monitoring electrical parameters in real time and for analysing energy consumption data.

An optional touch-screen tablet completes the system. It can be panel-mounted and is connected by Ethernet cable or Wi-Fi (via a router) for providing information to energy management software such as VERTELIS Suite.

For remote monitoring points, the user can also use the DIRIS B-30 measurement units with wireless or RS485 communication.

Advanced technology … made easy

The apparent simplicity of the concept is the result of SOCOMEC’s expertise in electrical measurement and communication technologies, as well a clear vision of what the measurement systems of tomorrow should be: accurate, flexible, multi-circuit, plug & play and cost-effective.

Concrete benefits

For contractors and panel builders:

• DIRIS Digiware is a plug & play solution: its RJ45 and RJ12 connections means that the modules can be very quickly integrated, as well as enabling the automatic configuration of the connected current sensors.

• DIRIS Digiware is above all a very cost-effective solution: implementation in a quarter of the time normally required, the compact design of the modules frees up more space in electrical equipment cabinets, and the common voltage measurement, display and communication functions offer up to 30% savings compared to existing metering technology.

For end-users:

• The accuracy of the system over a wide range of loads means it has unequalled precision in terms of energy measurements, thereby optimising any energy efficiency initiatives.

• DIRIS Digiware enables the identification of major loads and constantly monitors multiple electrical parameters for any anomalies. With its capacity to keep a check on the quality of electrical energy, the system can more easily anticipate network malfunctions.

• DIRIS Digiware is extremely flexible and is suited to the most space-constrained installations. The system can be easily retro-fitted in an existing facility thanks to the split-core current sensor options.

Compliance with standards: measurement accuracy is in accordance with standard IEC 61557-12: class 0.5 for the global measurement chain from 2 to 120% of nominal current (with TE current sensors).

Key points

- An innovative measurement system that is accurate, flexible, multi-circuit, plug & play and cost-effective

- Concrete benefits for installers, panel builders and end-users

- Implementation time divided by 4

- Up to 30% cost savings vs existing technology