www.magazine-industry-usa.com

17

'14

Written on Modified on

Milling in a new dimension

Protective systems for the machine giant

The name WaldrichSiegen Werkzeugmaschinen GmbH is known all over the world for producing large, high-precision gantry milling machines. Today gantry milling machines from WaldrichSiegen are at the heart of production plants wherever sophisticated workpieces are machined with highest precision. Telescopic covers from TSUBAKI KABELSCHLEPP are integrated into the machines from WaldrichSiegen to provide reliable protection for the cables and guideways.

The product portfolio from WaldrichSiegen comprises gantry milling machines as well as large machine tools for the areas of grinding, texturing and turning. The advanced technology is appreciated and sought after all over the world. Large machine tools manufactured by the company are supplied to many market leaders in China, e.g. to Dongfang. “There has been a partnership between WaldrichSiegen and Dongfang Electric and its subsidiary Dongfang Electric (Guangzhou) Heavy Machinery for many years,” confirms Ralf Tschersche, Product Manager for Milling Machines at WaldrichSiegen. The Chinese company Dongfang from the Sichuan province already purchased three horizontal turning lathes in recent years. In 2012 they then placed an order for a gantry milling machine: Dongfang Electric decided to buy the latest milling machine ProfiMill 8500/120-G for the factory in Guangzhou. It is to be used for the manufacturing of a variety of different power plant components.

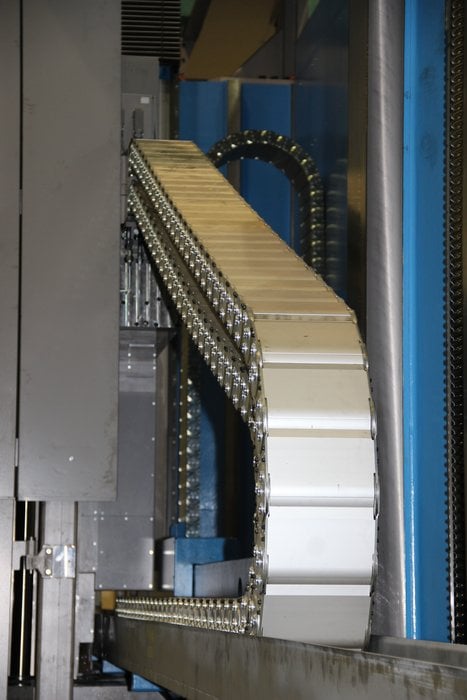

Photo: A steel cable carrier of almost 10 meters length from the S/SX 1800 model series from TSUBAKI KABELSCHLEPP in the ProfiMill 8500/120-G protects the electric and hydraulic cables

The order is for the largest gantry milling machine from the ProfiMill range that has ever been built by WaldrichSiegen: The distance between the two uprights is 8.5 meters, the clearance height is 7.5 meters. The milling and drilling unit at the heart of the system features an impressive 3.5 m travel length in the Z-axis and 120 kW power on the tool. “Especially for large dimensions, the gantry version provides the advantage of a clearly smaller footprint,” explains Ralf Tschersche. On the ProfiMill systems, modern control concepts with master/slave drives allow synchronized travel of all axes while the hydrostatic worm drive provides a high level of rigidity.

Machines and components: Everything on a larger scale

The enormous dimensions of the gantry milling machine for Dongfang required a custom solution from the start – also for the components used. WaldrichSiegen contacted the solution provider TSUBAKI KABELSCHLEPP with which they have had a close business partnership for many decades. Horizontal and vertical guideways, as well as the crossrail of the ProfiMill are equipped with telescopic covers from TSUBAKI KABELSCHLEPP (see box “Technical figures”). Travel lengths of up to 23 meters and travel speeds of up to 20 m/min have to be taken into account. The guideways are protected by tandem covers: This version with two coupled covers with 16 boxes each allows small outer dimensions even for long travel lengths. The highest travel speeds occur on the cross beam. In order to avoid the resulting vibrations and contact noise, the telescopic covers are equipped with special buffer damping in this case. The combination of special buffers creates soft damping of the moving mass.

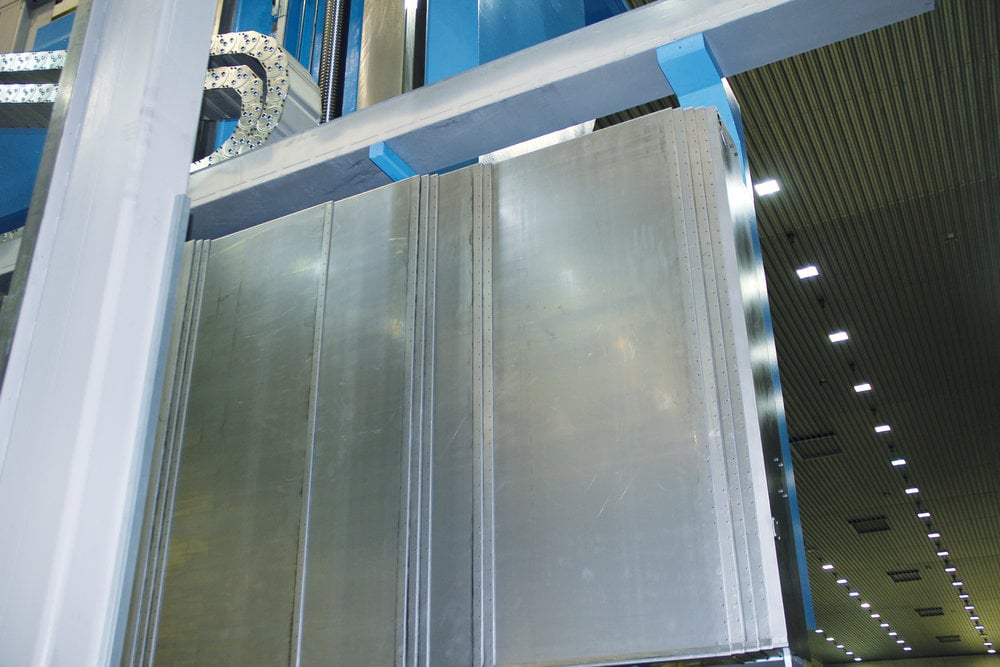

Photo: The highest travel speeds occur on the cross beams, so the telescopic covers are equipped with a special buffer damping

“KABELSCHLEPP develop and produce customer-specific guideway protection and conveyor systems,” explains Peter Marzinek, Head of Sales Germany/Switzerland/Austria at TSUBAKI KABELSCHLEPP GmbH. “There is a demand for KABELSCHLEPP telescopic covers from numerous machine manufacturers worldwide. We offer an immense variety of models and each cover is unique.” Wherever guideways, measuring equipment, drive elements or other sensitive parts on machines have to be protected, TSUBAKI KABELSCHLEPP have a suitable individual solution. The systems feature convincing reliability, long service life and innovative technology.

Customized systems for special requirements

In addition to the large dimensions, WaldrichSiegen had another special requirement: The guideway covers had to prevent leakage of oil and ingress of coolant – i.e. they had to be watertight. “Penetrating coolant would mix with the hydrostatic oil and affect the function of the machine,” explains Peter Marzinek. “The oil would consequently have to be changed which would result in great costs. Leaking oil would also harm the environment if it seeps into the ground.” In case of the horizontal covers, heat-bonded bellows installed between the boxes now protect against penetrating coolant. The vertical covers have a special slide contour, sealing strips between the boxes and deflection plates within the cover to prevent oil leaks. A wiper system with exchangeable lips additionally keeps the individual cover boxes clean.

Photo: The guideway covers prevent oil leakage and ingress of coolant

In addition to the telescopic covers, the ProfiMill for Dongfang is equipped with cable carriers from TSUBAKI KABELSCHLEPP with an unsupported length of 7.5 m. WaldrichSiegen chose a steel cable carrier from the S/SX 1800 model series. These are extremely robust, sturdy cable carriers for heavy mechanical loads and harsh environmental conditions which allow extensive unsupported lengths even with large additional loads. The proven steel cable carriers are equipped with extremely stable chain link plates, a joint design with a multiple stroke system and special bolts. The very large ProfiMill 8500/120-G includes a cable carrier with almost ten meters length which protects the electric and hydraulic cables.