www.magazine-industry-usa.com

03

'14

Written on Modified on

360 degree labeling with direct drive

Joint development: Motion control solution with integrated labeling controller

Ever more mobile electronic devices are firing up the consumption of batteries and rechargeable batteries - according to GfK from 116 million in 2008 to 300 million in 2012 in Germany alone. In light of these figures from the German consumer research association, productivity is crucial for cost-efficient production. During a redesign of the system, Schleuter mechanical engineers managed to increase the output of an existing battery labeling machine in China from 600 to 1000 units per minute. This increase was possible thanks to an automation including Motion Control that was integrated into the Kollmorgen drive control system.

Labels for batteries have two essential functions. Firstly, they convey information such as type designation, power, and brand. Secondly, they isolate the aluminum body, thereby preventing short circuits. The outer cover forms the positive pole for Mignon cells, which the negative pole is slid into when assembling. The plastic film material can only isolate the small energy storage device effectively after shrink fitting if the label is applied precisely after the battery has been assembled. This subprocess is critical for the entire manufacturing quality.

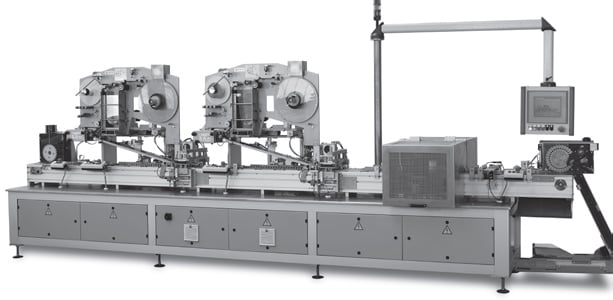

GU/BATII-DUO S is the Schleuter system which is today consistently driven by Kollmorgen servo technology. "For us, the use of servo technology for labeling batteries was equivalent to a quantum leap in productivity and precision," emphasizes Heinz-Jörg Fischer, Sales Manager at Schleuter. The automation at the heart of the GU/BATII-DUO S can also be found in an AKD PDMM. Together with Schleuter, Kollmorgen integrated the complete labeling control unit into this intelligent and freely-programmable servo controller. With their controller that was developed in-house based on Power PC architecture, and an operating system that is specially adjusted to it, the device range offers the computing capacity of an IPC uas part of a compact drive control unit. The master drive AKD PDMM can control two high-speed labeling machines at the same time with this performance. Moreover, there are still power reserves available for expansion.

Photo: Kollmorgen. Heinz-Jörg Fischer, Sales Manager at Schleuter, is convinced that "Kollmorgen offers the best technology for this application".

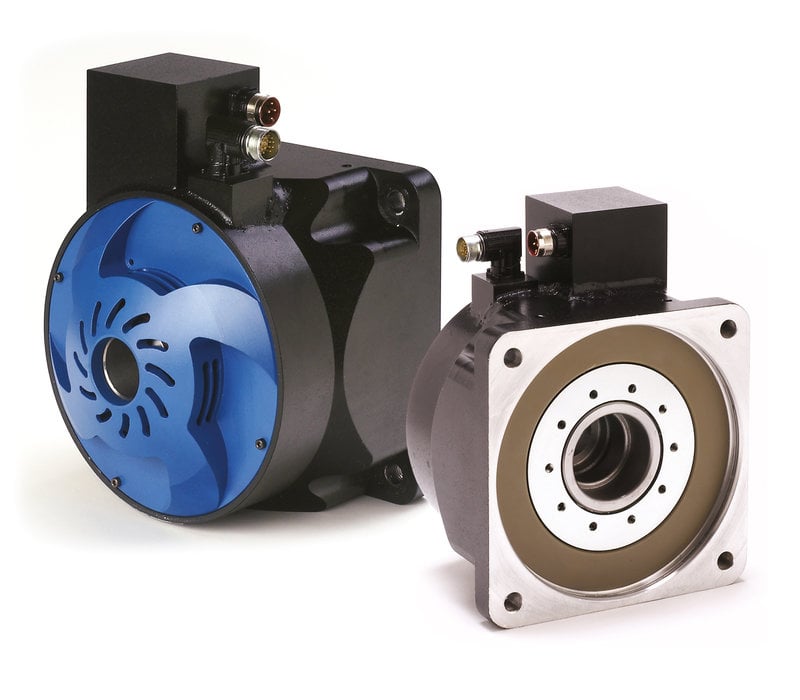

Furthermore, the AKD PDMM has the task of controlling the feeder belt's drive that ensures that the materials flow through the individual labeling stations of the machine. This axis is implemented electromechanically with a Kollmorgen CARTRIDGE DDR motor. At Schleuter, the synchronous servo motor works as a three-phase rotational direct drive (torque motor) and sits directly on the drive shaft of the roller conveyor. This ensures that it rotates continuously in the direction of the labeling when transporting the battery. By using direct drive technology with CARTRIDGE DDR motors, Schleuter was able to completely dispense with the gear units and bearings that had been previously required for the roller conveyor. This saves space, increases ease of maintenance and ensures more precise movements and dynamics due to the reduced dimensions and the absence of gear backlash. As part of the redesign, the rotor was clamped to the drive shaft of the chain belt in the machine and the stator was connected directly to the machine housing.

Precise labeling

The six single-phase servo axes are another part of the axis system that is synchronized by EtherCAT, consisting of controllers from the Kollmorgen AKD range and AKM-type synchronous servo motors. They have a total of four tasks. The drive of the infeed starwheel isolates the batteries from the store located above and drives these to the roller conveyor below. Two further axes take over the drive of the first labeling machine and a press-on belt, which presses the label tightly on to the battery before shrinking. The two processes are repeated for the second labeling machine. Finally, the sixth axis drives an ejector that unloads the batteries with production defects after analysis by inline high-speed image processing.

The total system works under a nominal load with a machine speed of 25.4 meters per minute. The GU/BATII-DUO S thereby achieves an output of 1000 units per minute - which corresponds to 17 labeled batteries per second. Finally, this productivity is also achieved as Schleuter does not run any individual process in the total system in cycles, but rather they run continuously. Here, the decision of the Bremen-based company to equip the machines with two cabling units comes into play. These do not work at the same time, but alternately. Due to the high production speed, one of the essential tasks of the machine operator is to ensure that there is a supply of labels. So that changing the rolls does not bring everything to a stop, both units are closely synchronized to each other in terms of the labeling control unit that is integrated in the AKD PDMM, so that switching between the units happens without stoppages or negative effects to the quality. The system even automatically detects up to where on the roller conveyor the batteries have been labeled - and then switches over seamlessly. After the switchover, the machine operator has enough time to equip the empty unit with a new roll and get it ready for operation.

High performance through co-engineering

The machine's performance cannot be put down to the hardware alone. Rather, it's the result of distributed intelligence, high computing power, and above all sophisticated software. This resulted from close collaboration between Kollmorgen and Schleuter. "This is a very innovative partnership," says Udo Wildenblanck, Industrial Automation Key Account Manager at Kollmorgen, who looks after and supports Schleuter. The AKD PDMM supplies the required computing power for this application thanks to a processing power of 800 MHz. The Siemens PLC is only used for display and formulation purposes at Schleuter. Data for AKD PDMM is exchanged via PROFINET.

Photo: Kollmorgen. Directly on the shaft: CARTRIDGE DDR motors drive directly.

Photo: Kollmorgen. Schleuter saves time when installing with the cable connection technology.

The entire system is programmed with the "Kollmorgen Automation Suite" development platform that is integrated in AKD PDMM servo controllers: On the one hand, the servo amplifiers feature a high-performance PLC and Motion Control functionality, on the other hand, motion sequences that are synchronized via the Pipe Network proven graphic programming environment are especially quick and easy to program. In addition, the five standardized languages of the IEC 61131-3 for the sequential control and the PLCopen Motion Control functional module for motion control are available. In this way, Schleuter and Kollmorgen disclosed all the controller data within the engineering project. Thereby all information from the system visualization onwards can be seen and parameterized. In this way, Schleuter ensures that is does not require another Engineering Tool. From diagnostics, to commissioning, through to operation and servicing: The same system is worked with throughout - including password protection. Heinz-Jörg Fischer is pleased to say that "Kollmorgen offers the best technology for this application".

Photo: Kollmorgen. The intelligent servo inverters from the AKD PDMM range offer the computing power of an "IPC inside". At Schleuter, communication takes place via EtherCAT.

Conclusion

The Schleuter system is a fine model for applications that require computing power, yet costly IPC solutions are ruled out due to comparatively low axis numbers. The balancing act starts here. If processes require the precise control of an IPC, then this is condensed as a proportionate cost block for "IPC per axis". If a compact controller is driven on the DIN rail instead of the more obvious route, the machine performance invariably drops through the limited process resources as a result of reduced cycle times with the regulation. With the AKD PDMM, Kollmorgen can offer a solution for this application that offers high performance without reductions in the price-performance ratio.

Author: Udo Wildenblanck, Key Account Manager, Kollmorgen, Ratingen