www.magazine-industry-usa.com

29

'14

Written on Modified on

CV-X200: unique stability, precision and speed thanks to record processing speed and 3D technology

This new vision system delivers far superior performance over the competition and is the first of its kind to allow connection of a profile measurement system all while remaining extremely easy to use.

This processing speed opens up new possibilities for users by allowing them to increase inspection reliability with multiple checks or filters in a single cycle time or by increasing camera resolution. For example, two 21M cameras with 109-ms transfer times, compatible with high throughput rates, can be connected to the CV-X200. The resulting images (5104 × 4092 pixels) make it possible to have a wider field of view (fewer cameras in cases of wide fields of observation) or capture higher-resolution images for increased and more stable detection. The processing speed allows the use of up to 20 filters. In general, between five and six filters are used with processing times that remain as low as a few milliseconds, a rate that is not possible with the competition.

Combination with 3D technology

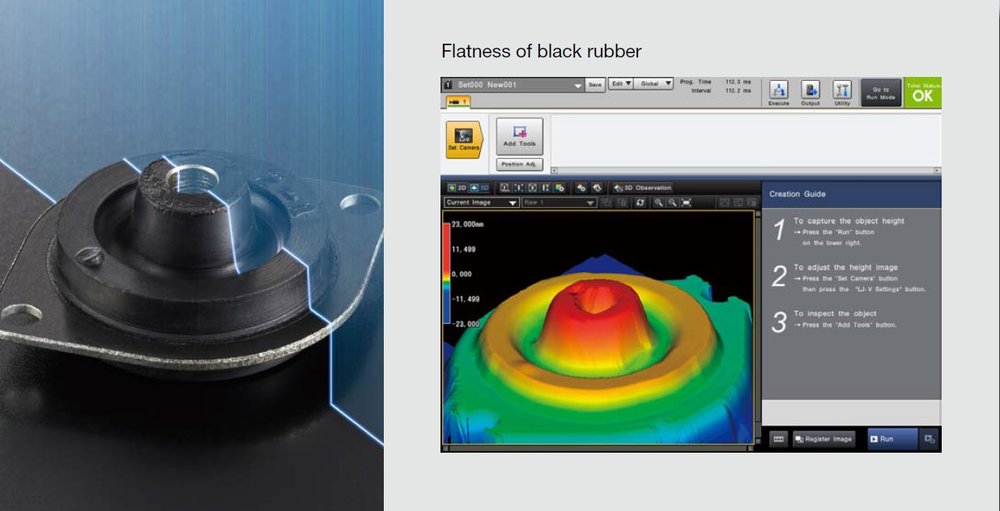

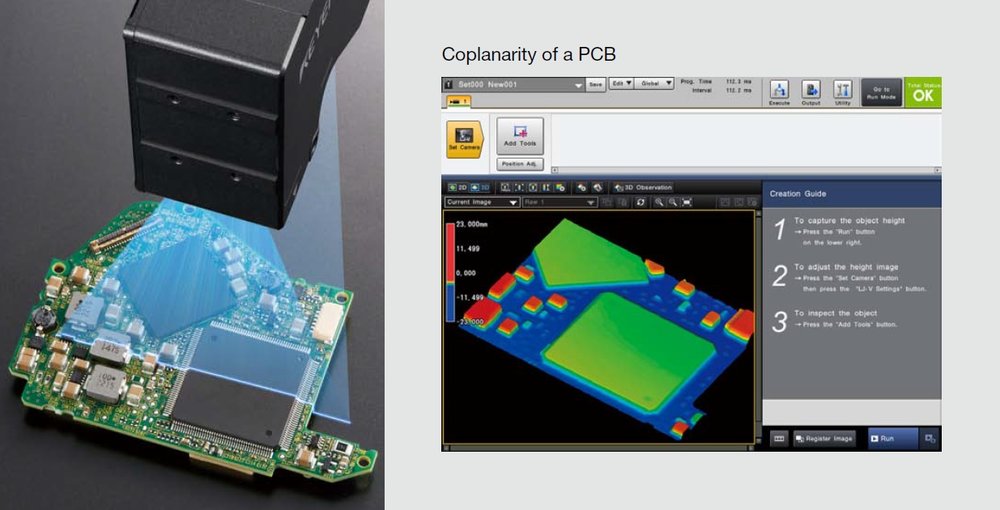

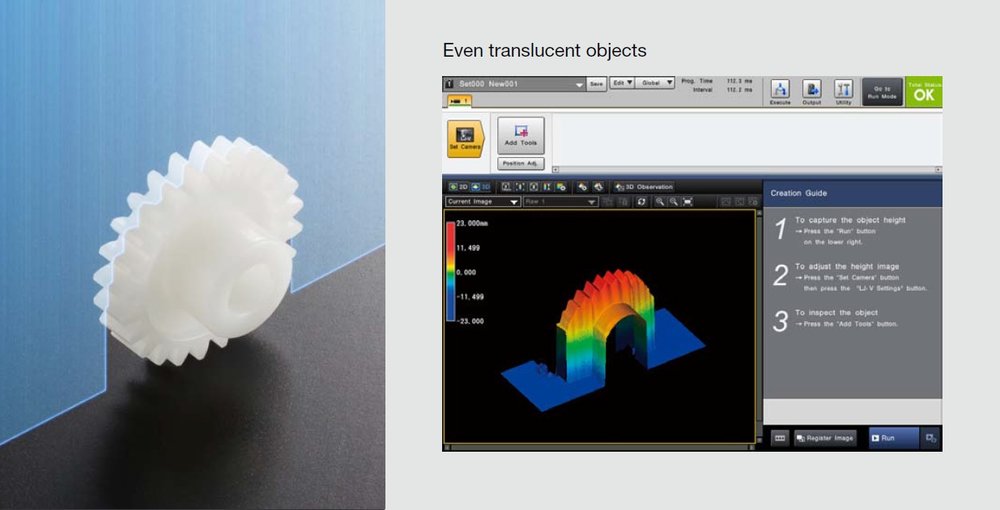

Keyence's LJ-V Series high-speed inline profilometer can be connected to the CV-X200 to create a turnkey 3D-measurement solution that is both particularly easy to set up and use. With a sampling speed of 64,000 profiles per second – the fastest in the world – the LJ-V Series allows for 3D inline profile measurements, making it a complementary addition to vision systems. Keyence's proprietary laser triangulation measurement method makes it possible to achieve extreme precision and overcome problems of lighting or of insufficiently or overly reflective surfaces. The resulting profiles can be processed by the CV-X Series' functions. This also opens up new possibilities. For example, height measurements can be made on surfaces and OCR can be performed on surfaces that usually throw off vision systems, such as moulded letters on tyres and laser or dot-peen markings on metal parts.

The CV-X Series allows for many combinations: as many as four cameras from a range of 18 can be connected to a single controller. The same is true for the LJ-V Series (up to four), which can also be combined with cameras.

New algorithms

Two new image-enhancement filters have been added to the CV-X Series' already extensive catalogue of functions. The first filter, Scratch Defect Extraction, is a new and unique function for detecting linear defects on rough surface conditions. The Noise Isolation filter eliminates or extracts stains and is particularly useful when background noise hinders image processing or to detect subtle stains.

Maximum simplicity

The CV-X200 Series features the same advantages that have made the CV-X Series famous. It has been designed to simplify all the complex steps involved in using a vision system. Aimed at end users, the CV-X200 Series' menus are intuitive and use straightforward language and its tools are sorted into categories. Operators simply select the ones they need and follow the setup steps in the order given by the software. The context-sensitive help provides the information needed to easily understand each operation. As a result, even the most complex detection tasks can be performed by any operator.

Coplanarity measurement of a printed circuit board

Profile analysis of a translucent object

Profile measurement on an elastomer part