www.magazine-industry-usa.com

23

'14

Written on Modified on

Opening of the new forging unit for Vossloh Cogifer Kihn

On May 21st 2014, Vossloh Cogifer opened its new forging unit for manufacturing forged tongues on the Vossloh Cogifer Kihn industrial site in Luxembourg. The event took place in the presence of Mr. Etienne Schneider, Deputy Prime Minister, Minister of the Economy. The whole Vossloh Cogifer and Vossloh Group Managing Board attended the opening and welcomed their major customers and partners.

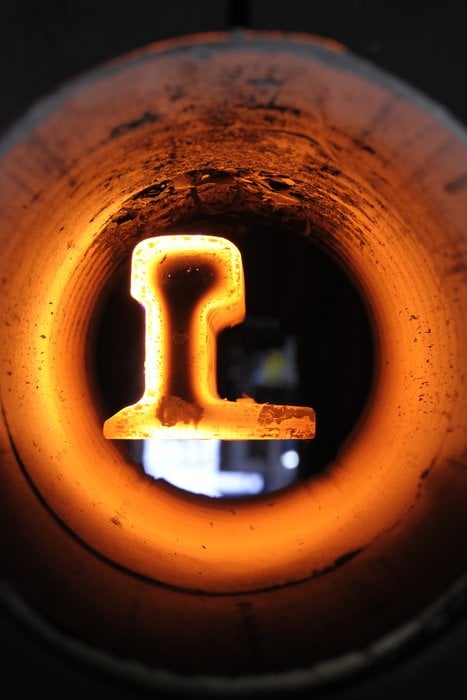

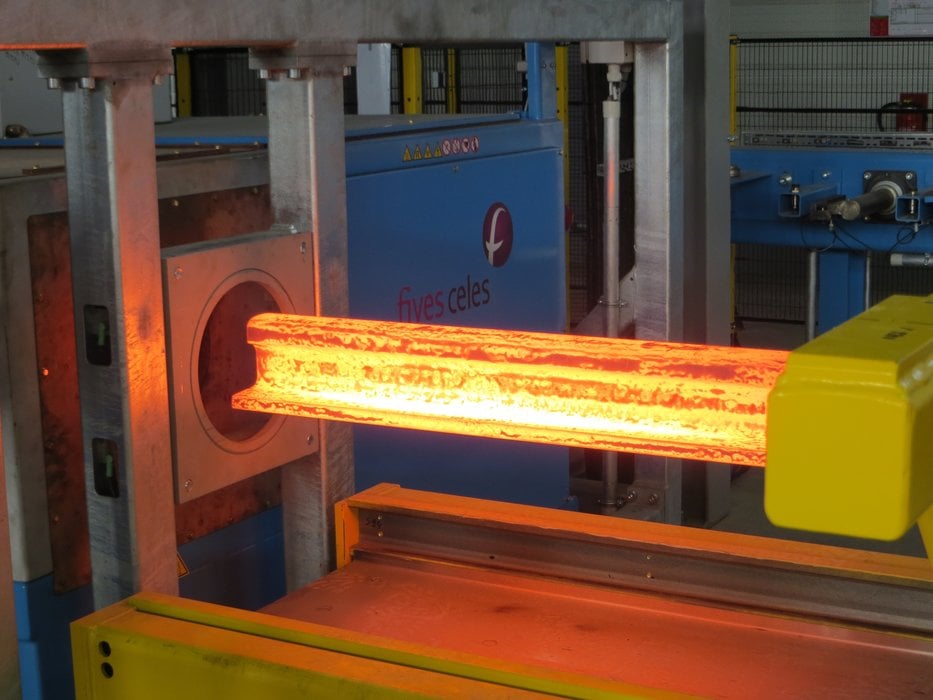

In both, conventional and very high-speed rail applications, the forged tongue is a key component of track points and crossings. The profile of the switch rail is different from that of the connecting rail, which has a running profile. Forging is performed at the heel of the switch rail, enabling the intermediate railway to be welded to the adjacent rail.

Founded in 1893, the Luxembourg subsidiary of Vossloh Cogifer, Vossloh Cogifer Kihn, has been manufacturing forged tongues for the group, as well as for many national rail networks (DB, RFI, SNCF, etc.) for decades. This is a demanding market, in terms of quality and safety, and Vossloh Cogifer Kihn supplies forged switches - of any standard required - to customers all over the world. With this expertise, in 2007, Vossloh Cogifer contributed to the record-breaking high speed railway journey in which a train on the Paris-Strasbourg (France) line crossed points at a speed of 560 km/hr.

With industrial investments of 15 million euros, Vossloh Cogifer has strengthened its forging expertise with its own centre of excellence in the heart of Europe.

In order to meet the growing demand on the market, Vossloh Cogifer today is able to manufacture over 20,000 forged tongues a year. With this increased production capacity, Vossloh Cogifer can provide greater flexibility and respond faster to its customers' needs.

On March 20th 2013, Etienne Schneider also attended the ceremony in which the first stone of this project was laid. This investment commitment witnesses Luxembourg's interest in industrial activities with high value added.

Fourteen months after the foundation stone ceremony the new 4000 m2 production hall now houses a range of high-tech machinery, delivering on an extremely innovative forging process, including a new 50,000 kN forging press, and a milling machine with self-adjusting clamps, controlled by a set of automatic conveyors for switches that can be up to 42 m long.

As stated by Christophe Louppe, the project manager for this new unit, The new forging unit brings together all the expertise and industrial excellence of Vossloh Cogifer, in terms of quality, safety and environmental protection."

The site will also sustain employment in a region that has a long tradition of steel and metal-working.

"At the heart of the group's strategy, this Forging Centre of Expertise is one of a number created on the basis of long experience and know-how in specific sites, such as the Reichshoffen Technology Centre (France) and the Outreau Foundry Centre of Expertise (France). All these are aimed at expanding Vossloh Cogifer s switch technology worldwide" added Didier Mainard, Chief Operating Officer of

Vossloh Cogifer.