www.magazine-industry-usa.com

12

'14

Written on Modified on

On-site hygienic servo solution

Kollmorgen develops servo solutions for greater design freedom

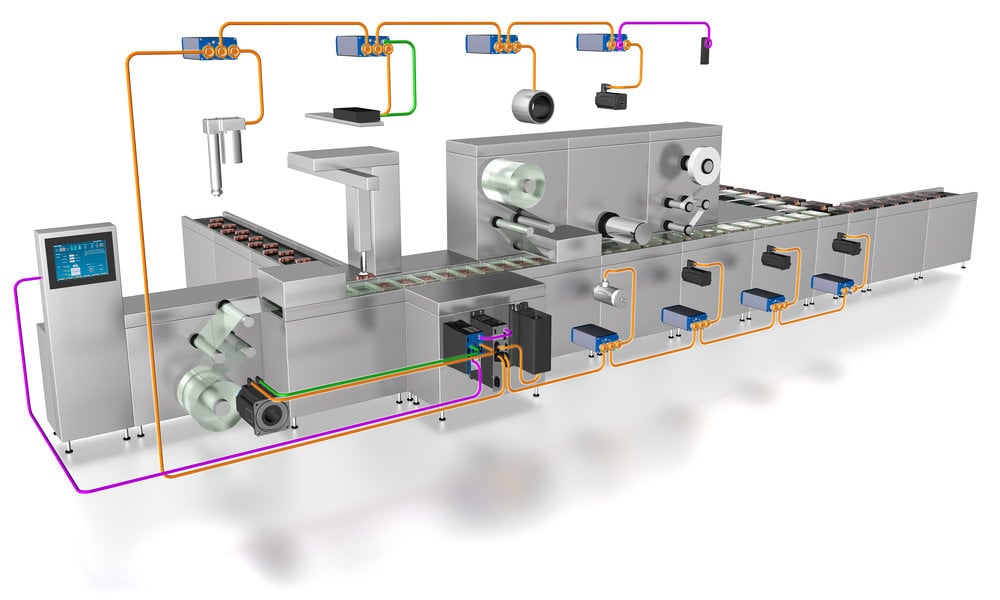

With AKMH stainless steel motors (http://www.kollmorgen.com/en-gb/products/motors/servo/akmh-series/akmh-stainless-steel-series/), Kollmorgen has developed a scalable solution for motor tasks in the packaging, food processing and pharmaceutical industries. The motors promote an open machine design thanks to their innovative construction. Therefore, because a covering is not required, cleaning is much faster. Also, no bacteria pockets can build up on the motor itself which then reduces the risk of product contamination and possible recalls.

Photo: Kollmorgen Stainless Motor AKMH

The AKMH range is constructed within the IP69K protection class for standard cleaning and also cleaning performed with steam jets. The use of stainless steel 1,4404 makes the servomotor corrosion-resistant − even against aggressive cleaning agents.The compact unit in sizes two to six are therefore used specifically in machines with direct product contact and aseptic processes. The AKMH stainless steel motor effectively guides the heat loss away and thus lowers the derating. Consequently the range, which is FDA-certified and has been developed in accordance with EHEDG guidelines, delivers higher continuous torque with smaller volumes. The clean power packages are connected consistently via a single cable including feedback with the SFD3 digital resolver or DSL Hiperface. One instead of two: By halving the installation complexity, cleaning is much easier and the risk of leakages is reduced.

The role of corresponding servo drives for use in hygienically demanding food and packaging industries is diminishing, and Kollmorgen supports this trend with its decentralized servo amplifiers (http://www.kollmorgen.com/en-gb/products/drives/servo/akd-n/akd-n-decentralized-servo-drive/) from the AKD-N range. When placed in the direct vicinity of motors, the robust IP67 device reduce the control cabinet volume and wiring effort by more than 80%, depending on the application. Another effect: Because less heat is lost in the control cabinet, less air conditioning is required. The improved thermal properties of solutions that are spaced apart side by side prevent further derating and consequently, in comparison with solutions which are directly combined with each other, deliver 100% power. Because the AKD-N can be combined with any servomotoror rotary or linear direct drives, in comparison with integrated solutions, the design possibilities are endless.

Photo: Kollmorgen ServoDrive Decentraized AKD-N OneCable

IMAGE MATERIAL: www.gii.de