www.magazine-industry-usa.com

28

'19

Written on Modified on

3D Systems Unveils New Production Solutions; Ushers in Era of True 3D Production at Formnext 2019

World leader in production solutions for additive manufacturing demonstrates latest innovations for Healthcare, Aerospace, and Automotive industries.

At Formnext 2019, 3D Systems (NYSE:DDD) is showcasing its new, application-specific production solutions for the Healthcare, Aerospace, and Automotive industries. The company has the unique ability to architect solutions specific to customers’ needs through a combination of its breakthrough materials, hardware platforms, software, and professional services - creating a path forward to integrating additive into traditional production environments. As a result, manufacturers are able to achieve design freedom, increase agility, scale production, and improve overall total cost of operation.

“In 2016, I shared my vision and strategy for how 3D Systems would make 3D production real. It would require customer collaboration and innovation, with the experience and expertise of our people as a driving force,” said Vyomesh Joshi, president and chief executive officer, 3D Systems. “Today, we’re executing on that strategy to position 3D Systems as the premier production solutions company in the industry. In fact, we have already surpassed 175 million production parts created by our customers, and we are on our way to 200 million parts created in 2019 using 3D Systems’ solutions.”

3D Systems’ customers realizing the benefits of the company’s production solutions span a range of industries including Healthcare, Dental, Aerospace, Automotive, and Durable Goods. Some examples include:

- Align Technologies incorporates 3D Systems’ technology to help produce more than 430,000 Invisalign aligners per day – the single highest volume additive workflow in the world.

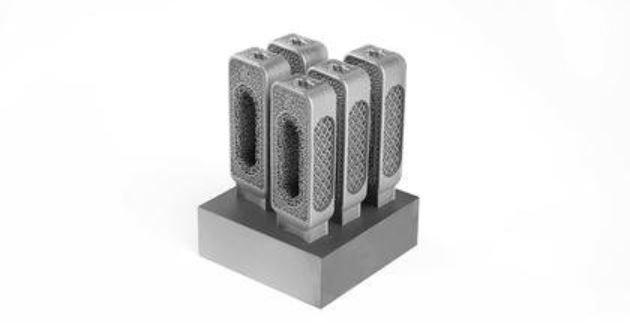

- NuVasive – an orthopedic device company – that capitalized on 3D Systems’ production solutions to move from design to market of Modulus® (now a full implant line) in just over one year.

- Delft Aerospace Rocket Engineering team at the University of Delft partnered with 3D Systems to develop an innovative rocket exit nozzle as a single part, 3D printed in titanium. Firing tests of the completed nozzle proved to be successful, placing them one step closer to achieving their mission of sending a rocket into space.

Production Solutions Accelerating Adoption of Additive Manufacturing

3D Systems partners with customers to help them progress through their additive manufacturing journey and accelerate the adoption of additive within their existing production environments. This process begins with the customer’s application in mind; designing the best possible solution to achieve their needs and successfully address challenges.

3D Systems encourages customers to begin their additive manufacturing journey by engaging with one of its Customer Innovation Centers (CIC). There, a customized production workflow solution will be designed to accelerate the development of advanced applications by providing customers with access to bespoke solutions, domain expertise, and state-of-the-art technology. The process begins with the company’s software as the core to the overall solution.

Customers will be able to scan and digitize solutions – if digital files do not exist – and then prepare their CAD file to optimize it for 3D printing. This preparation step includes importing part data, orienting the part on the build plate, optimizing the geometry and creating optimal supports to ensure the final part matches the design intent. From this point, the part is created using 3D Systems’ additive manufacturing hardware platforms. After printing, it is post-processed and 3D Systems’ software comes into play again to inspect the part.

www.3dsystems.com