www.magazine-industry-usa.com

23

'12

Written on Modified on

EEC One: An easy start in automation

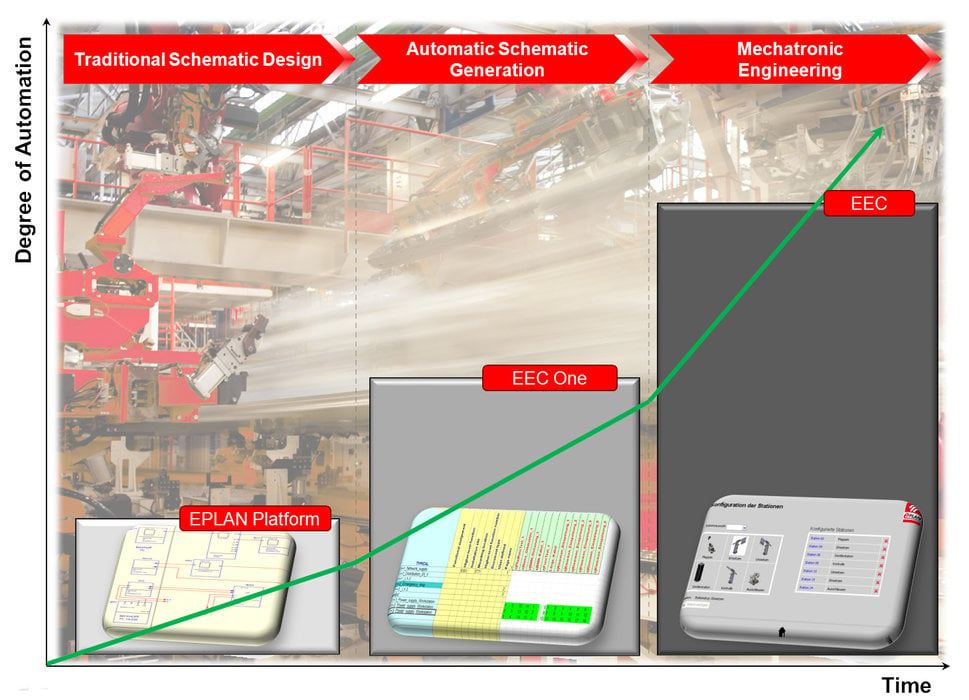

Experts agree: The true potential savings in engineering lie in automation and standardisation. The new EPLAN Engineering Center One closes the huge gap that often exists between conventional and mechatronic engineering. Predefined standards such as macros or value sets can be combined automatically to a schematic through MS Excel. Solution provider EPLAN will present its new development at this year's Hanover Fair.

Digital Factory: Hall 7 / Stand D18

The move of the Digital Factory to Hall 7 was not the only surprise in advance of the Hanover Fair this year. EPLAN also surprised the branch by announcing the new EPLAN Engineering Center One, in short, the EEC One. The system is a decisive building block in a consistent automation strategy that assists companies every step along the way from the introduction of CAE software via standardisation and automation through to mechatronic engineering. Based on MS Excel, it allows electrical and fluid schematics to be generated automatically.

A solid foundation

The designer can already start with automation when the EPLAN Platform is used. In the CAE system project templates, partial circuits (macros) or reports can be structured. Once the standards such as value sets of a motor output or the terminals used have been defined, EEC One comes into play. Individually developed project standards can be combined in spreadsheet form via an MS Excel front-end. Selection is facilitated by the integrated macro preview, which displays variants comfortably. The selected macros can be integrated in the spreadsheet by dragging-and-dropping. Decisive practical advantage: The macros automatically include their freely configurable parameters in the MS Excel front-end. Furthermore, extensive sets of rules can be created in MS Excel – thus avoiding the tedious work of entering the parameters manually. The design guidelines created in the process ensure maximum transparency and top quality in the schematics. Electrical or fluid schematics can thus be generated automatically at the click of a button. Companies profit three-fold from this automation strategy: Standards are created once in high quality; sets of rules secure the know-how centrally and automation of the documentation reduces the lead times considerably.

Mechatronic engineering

What succeeds on a small scale also functions on a large scale. The existing standardisation of the CAE data is in this case implemented across disciplines. With the EPLAN Engineering Center as the next configuration level, the mechanical, PLC or documentation data are also included in the standardisation. The EEC generates all of the documentation at the click of a button: Schematics and fluid plans, mechanical designs, and complete PLC programs. This is the effect of a cross-discipline module with which the machine can be assembled functionally. The benefits are clear: All the data is recorded centrally in the system. All the generated documentation elements are perfectly attuned to each other. And finally, downstream processes such as commissioning now require few or no further changes.

The upshot:

The new EPLAN Engineering Center One closes the huge gap often existing between conventional and mechatronic engineering. On the basis of this new consistent automation strategy, companies are assisted every step along the way from the introduction of CAE software through to mechatronic engineering.