www.magazine-industry-usa.com

17

'19

Written on Modified on

"Image to information" with NXT Machine Vision

Industrial cameras of the IDS NXT family generate valuable information directly from image data through AI-based image processing.

The vision app-based IDS NXT platform represents the base for a new generation of highly versatile industrial cameras from camera manufacturer IDS Imaging Development Systems GmbH. With their high-performance, freely programmable hardware in the housing of standard industrial cameras in combination with the unique vision app concept, the new IDS NXT rio & rome models are more than just image providers and represent a new evolving stage of digital industrial cameras. Powered by deep learning algorithms, they perform autonomous tasks or support PC applications or machine controllers with pre-processed data. Despite all this, they offer the functionality and data transfer performance of a standard industrial camera with GenICam interface. With this new camera family, IDS combines two devices in one.

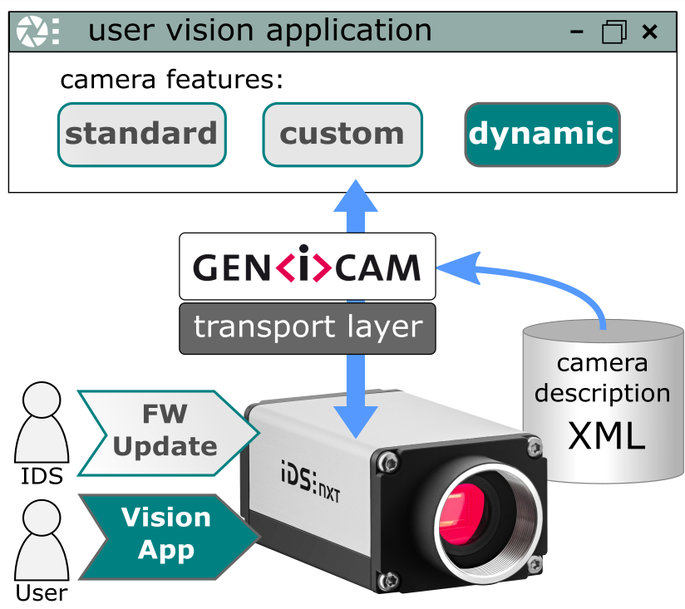

With their app-based approach, these cameras are as versatile as smartphones. Their industry-standard camera functions can be easily extended by the user via individual image processing operations with so-called vision apps. Recurring tasks, such as reading codes, characters or number plates, as well as finding, measuring, counting or identifying objects, can be set up and changed quickly. Through "Smart GenICam", configurations, controls and results of such vision apps are also available via the camera's XML description file in any GenICam-compliant third-party application, such as HALCON. Users therefore do not have to wait long for a firmware update from the manufacturer or even look for another model because of urgently needed camera features. With Smart GenICam, even self-programmed camera functionalities can be queried and executed from any GenICam application like any other manufacturer camera feature without additional driver software. Their development completely follows the same principles as with GenICam cameras. Camera features are programmed like normal camera applications on the PC with an IDS NXT camera and converted by the vision app development kit for execution on-camera into a vision app with just a click of a button. This distinguishes the IDS NXT product families from typical smart cameras which usually have PC-like operating systems that are developed and communicated with in a completely different way to a classic industrial camera. IDS NXT, on the other hand, aims to support the working methods of each user group rather than changing them.

Figure 1 Even self-programmed vision apps can be queried and executed from any GenICam application using Smart GenICam like any other camera feature from the manufacturer.

AI-powered image processing

The camera hardware platform is supported by a parallel working FPGA that can be reprogrammed at runtime, making the complete data path flexible to use. With a KI-Vision app developed by IDS, this integrated FPGA becomes a KI processor capable of accelerating many well-known architectures of neural networks.

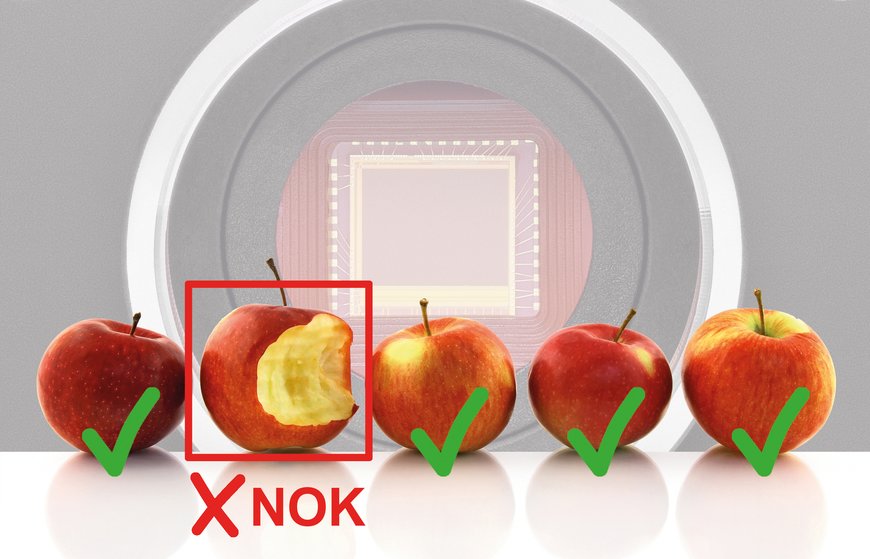

Artificial neural networks now interpret complex image content with unreached accuracy and offer solutions that could not be realized by manual programming with fundamental algorithms, even with great effort. Image processing powered by artificial intelligence begins where classical image processing struggles. For instance, in order to continuously reduce error rates in a production environment, production errors must be detected and avoided at an early stage. AI-based procedures provide new, more effective approaches where it is almost impossible to predict the complete variety of possible deviations and errors completely. Using a neural network trained with a large number of sample images, the camera software can recognize known features in new image data (feature extraction). Feature relationships and weights (feature combination) then allow conclusions to be drawn about given result classes and their probabilities. With machine learning it is very easy to detect deviations (anomalies), classify objects, check surfaces for quality and defects or verify printed circuit boards and their assembly.

The diversity of neural networks is made accessible to users through a wide range of open source frameworks, high-level software and services. A multitude of published neural network architectures already cover different requirements for complexity, accuracy or inference times. Automation and monitoring of industrial plants provides more and more suitable image data for the training of these architectures.

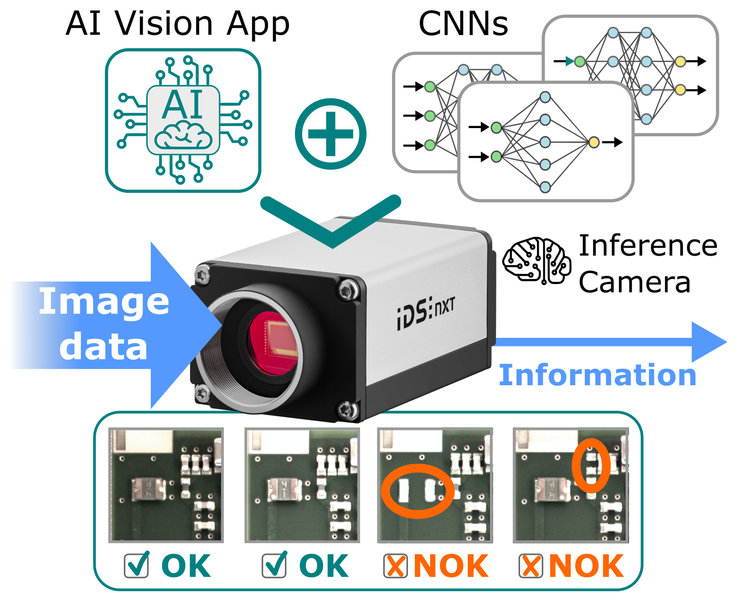

„Image to information on-camera"

The interpreter application "IDS NXT ferry", specially developed for compatible network architectures, converts existing, already trained neural networks for use on the embedded vision platform. Users can thus conveniently provide their own neural networks to the IDS NXT inference camera for various tasks, which in addition to generating image data also directly takes care of the analysis and evaluation of this information. Determining the information content and thus a data reduction then already takes place decentrally in the camera, which avoids bandwidth bottlenecks in the data transmission. With the distribution and networking of such "cyberphysical components", direct process data will become available according to the internet of things approach, which will sustainably boost the automation and processing speed of industrial manufacturing processes.

Figure 2 Decentralized image analyses generate process-relevant information directly in the camera.

The FPGA-based acceleration of artificial intelligence allows inference times of only a few milliseconds with common neural network architectures. Cameras based on the IDS NXT platform can thus keep pace with modern desktop CPUs in terms of accuracy and speed of results - with significantly less space and energy consumption at the same time. The re-programmability of the neural network accelerator offers additional advantages in terms of future security, low recurring costs and time-to-market. AI technology is advancing so rapidly that new frameworks and architectures are being added every month. These can be integrated by the manufacturer via software without changing the hardware platform and users do not have to purchase new devices. The fast reconfiguration of the dedicated processor also allows switching between several loaded neural networks within a few milliseconds during runtime. This enables the sequential execution of different classifications with the same image data within a vision app.

Forecast

Artificial neural networks have already proven their additional value for the modern machine vision world. Machine object recognition and classification are two of the most important new capabilities that industry automation brings forward, as well as many applications in other markets. The flexible customization of the IDS NXT platform simplifies its integration into an existing system and adaptation to different markets. Equipped with this AI-based embedded system, the user can conveniently deploy his own neural networks in the inference camera for different tasks. For completely autonomous, PC-independent operation in industrial environments, model variants of the industrial cameras with industrial protocols such as PROFINET or OPC-UA will also be available. Starting in the second quarter of 2019, IDS will show an easy controllable way to quickly and easily bring AI-supported image processing to the machine as a complete embedded vision system with IDS NXT industrial cameras.

Author

Dipl.-Ing. Heiko Seitz

Technical Writer

IDS Imaging Development Systems GmbH

Dimbacher Str. 6-8

74182 Obersulm

Germany

T: +49 7134 96196-0

E: This email address is being protected from spambots. You need JavaScript enabled to view it.

W: www.ids-imaging.com

© 2019 IDS Imaging Development Systems GmbH