www.magazine-industry-usa.com

29

'10

Written on Modified on

43% less energy consumption

With its newly developed TopTherm fan-and-filter units, Rittal is showing that significant improvements in ventilation are still possible. The innovation is the first in the world to use diagonal technology. When installed, it ensures a far better air throughput for improved ventilation in enclosures and housings. Other convincing advantages, besides the simple, tool-free assembly, are the ease of maintenance and increased efficiency. Extensive tests haven shown energy savings of 43%.

Using diagonal fan technology, Rittal has succeeded in creating an intelligent synthesis of radial and axial ventilation in its new TopTherm fan-and-filter units. The new fan technology is characterised by the fact that the air outlet direction is not, as previously, in the fan's axial direction but instead diagonally to the outside. This favours an even distribution of air in the enclosure or housing, and avoids the formation of hot spots.

In addition to the flat design, the key benefits are the steeper curve and the higher pressure saddle. As a result of this, the system has got higher pressure stability and – when installed and under operating conditions – provides a higher and more constant air flow over a wide area. This in turn means an increased operating life for the filter mats without having to settle for any loss of power in return.

Rittal has conducted extensive tests that allow a direct comparison between the old and new technologies, in order to demonstrate the performance of the new fan-and-filter units. A conventional fan-and-filter unit and a new TopTherm unit were installed in each of two identical test setups. The enclosures used were equipped with a heater and temperature sensors. Both fan-and-filter units were controlled by a digital enclosure temperature controller during the one-and-a-half month test period. The result: Thanks to the benefits of the new diagonal fan-and-filter unit, the running time of the TopTherm filter was cut by around 40%. The power consumption was thus around 43% below the conventional level.

Through completely tool-free assembly, the fan-and-filter units can be simply mounted and the air flow direction can be quickly changed. Electrical connections can be made easily, and maintenance, including filter mat replacement, is conducted without a hitch. During installation, the tried and tested, snap-on mounting system allows the easily insertion of the fan-and-filter units into the prepared mounting cut-outs. The dimensions of the mounting cut-outs are identical with those of previous models. Spring-type terminals, into which the wires or conductor sleeves are inserted, replace conventional screw terminals when making electrical connections.

A new release mechanism lets the louvered grille fold down forwards during maintenance work, snapping into position at an opening angle of around 70°. This lets the user now have both hands free to replace a filter mat. The feature means less additional maintenance and reduced costs. The procedure is the same with the outlet filters.

To improve performance, several fan-and-filter units can be seamlessly bayed to one another without leaving any disturbing gaps TopTherm fan-and-filter units are available in various outputs, ranging from 20 m3/h to 700 m3/h. There is also a choice of 24 V (DC) or 115 V, 230 V and 400 V 3-phase (AC, 50/60Hz) supply voltages.

Besides the standard fan-and-filter units, an EMC version is also available.

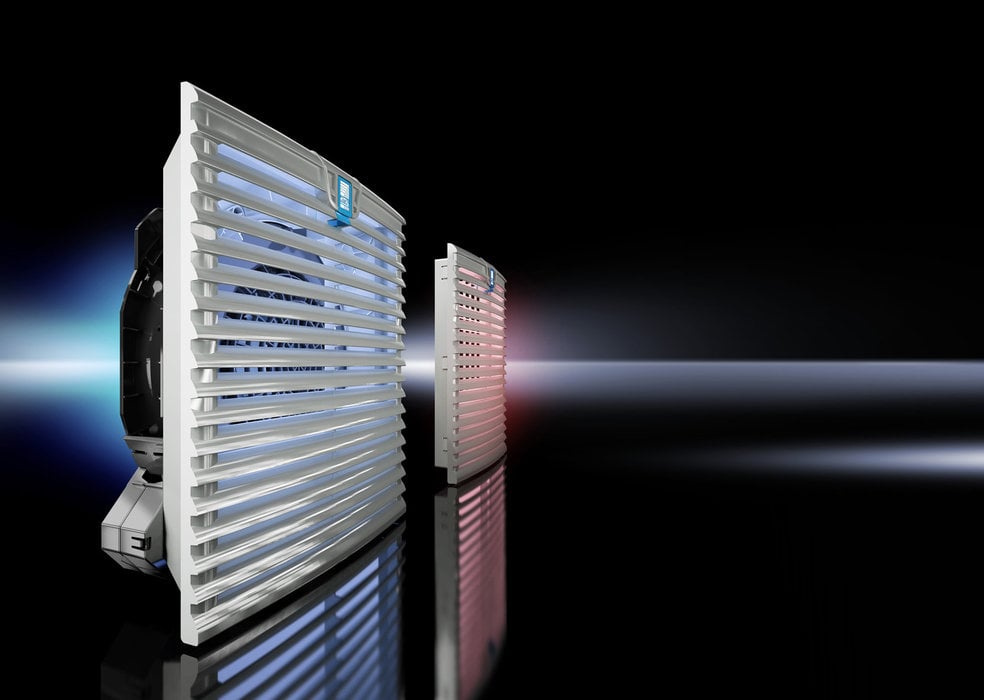

Caption

Rittal TopTherm Filterlüfter.jpg: TopTherm fan-and-filter units – Extensive tests haven shown energy savings of 43 percent.

Reproduction free of charge. Please specify "Rittal GmbH & Co. KG" as source.

In addition to the flat design, the key benefits are the steeper curve and the higher pressure saddle. As a result of this, the system has got higher pressure stability and – when installed and under operating conditions – provides a higher and more constant air flow over a wide area. This in turn means an increased operating life for the filter mats without having to settle for any loss of power in return.

Rittal has conducted extensive tests that allow a direct comparison between the old and new technologies, in order to demonstrate the performance of the new fan-and-filter units. A conventional fan-and-filter unit and a new TopTherm unit were installed in each of two identical test setups. The enclosures used were equipped with a heater and temperature sensors. Both fan-and-filter units were controlled by a digital enclosure temperature controller during the one-and-a-half month test period. The result: Thanks to the benefits of the new diagonal fan-and-filter unit, the running time of the TopTherm filter was cut by around 40%. The power consumption was thus around 43% below the conventional level.

Through completely tool-free assembly, the fan-and-filter units can be simply mounted and the air flow direction can be quickly changed. Electrical connections can be made easily, and maintenance, including filter mat replacement, is conducted without a hitch. During installation, the tried and tested, snap-on mounting system allows the easily insertion of the fan-and-filter units into the prepared mounting cut-outs. The dimensions of the mounting cut-outs are identical with those of previous models. Spring-type terminals, into which the wires or conductor sleeves are inserted, replace conventional screw terminals when making electrical connections.

A new release mechanism lets the louvered grille fold down forwards during maintenance work, snapping into position at an opening angle of around 70°. This lets the user now have both hands free to replace a filter mat. The feature means less additional maintenance and reduced costs. The procedure is the same with the outlet filters.

To improve performance, several fan-and-filter units can be seamlessly bayed to one another without leaving any disturbing gaps TopTherm fan-and-filter units are available in various outputs, ranging from 20 m3/h to 700 m3/h. There is also a choice of 24 V (DC) or 115 V, 230 V and 400 V 3-phase (AC, 50/60Hz) supply voltages.

Besides the standard fan-and-filter units, an EMC version is also available.

Caption

Rittal TopTherm Filterlüfter.jpg: TopTherm fan-and-filter units – Extensive tests haven shown energy savings of 43 percent.

Reproduction free of charge. Please specify "Rittal GmbH & Co. KG" as source.