www.magazine-industry-usa.com

10

'18

Written on Modified on

Special prize for “Flexible Production” awarded to the Festo Motion Terminal

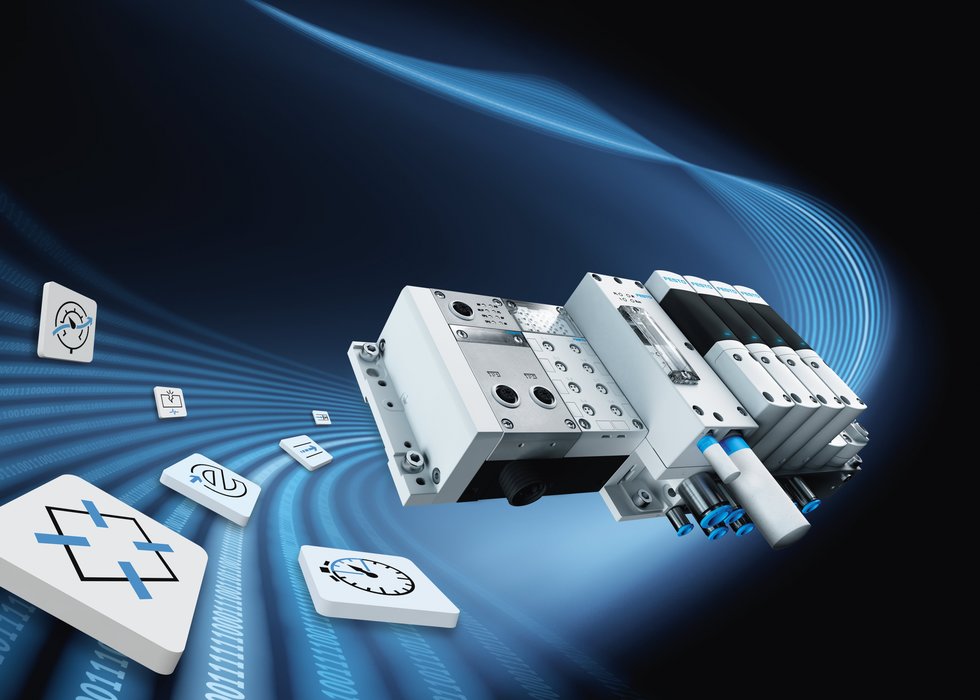

With the Festo Motion Terminal, Festo has made a technological leap forward by merging hardware and software to form a digitised valve. "Festo Motion Terminal has digitised pneumatics for the first time. This enables highly flexible production," explained the jury in its statement. With the Festo Motion Terminal, Festo has made a technological leap forward by merging hardware and software to form a digitised valve.

A revolution in pneumatics

All kinds of valve functions can be programmed flexibly and controlled via motion apps. The Festo Motion Terminal combines the functions of more than 50 individual components, thus hugely simplifying the engineering process and greatly reducing the number of hardware components. Machine and equipment manufacturers can use entirely new platforms and modular designs. Equipment operators gain competitive advantages thanks to flexible and adaptive systems, data transparency, communication capabilities, outstanding process reliability and simpler operation of complex machines. Alfred Goll, Spokesman of the Management Board of Festo AG, says: “We have created an automation platform which integrates all the functions required for economically setting up adaptive and flexible production – this is a revolution in the field of pneumatics!”

Applications in the process industry

At ACHEMA, Festo will showcase the Festo Motion Terminal VTEM for the first time using applications specifically for the process industry. Improved energy efficiency and self-adaptation to process deviations are made possible with simple commands thanks to the software that is embedded directly at field level. There’s no need for maintenance staff to physically intervene. “We want to discuss the potential benefits for plant operators, OEMs and manufacturers with interested visitors at ACHEMA on the basis of actual examples,” explains Dr. Eckhard Roos, Head of Global KAM and ISM Process Industries.

The ACHEMA innovation award

This was the eight year that trade media organisations PROCESS, PROCESS Worldwide, PharmaTEC, LABORPRAXIS and LAB Worldwide handed out the award. They were looking for the most innovative equipment, systems and processes exhibited at ACHEMA 2018. The award ceremony was held at ACHEMA in Frankfurt on the 12th of June 2018.

www.festo.com/us