www.magazine-industry-usa.com

13

'17

Written on Modified on

Reliable detection of objects and fill levels

Whether solid, liquid or granular – capacitive sensors are able to detect a multitude of different objects in a contactless and reactionless manner regardless of their material and shape. With its portfolio of optoelectronic and inductive switches, which now includes capacitive proximity switches, Leuze electronic can provide users with complete solutions for virtually all detection requirements in automation from a single source.

The operating principle makes the difference

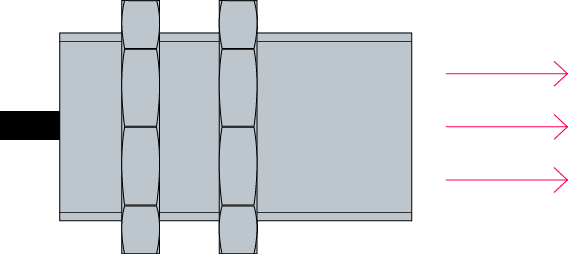

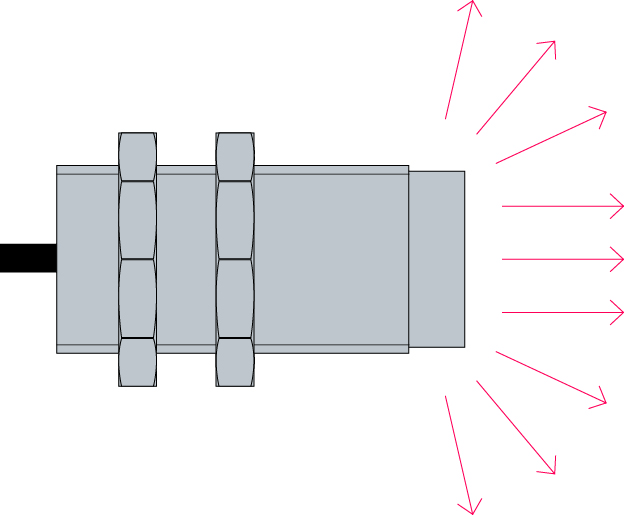

The unique feature of capacitive sensors: These proximity switches demonstrate their strengths wherever other measurement principles no longer function. These strengths include in particular their high sensitivity as well as their ability to detect both electrically conductive and non-conductive objects. From a technical viewpoint, a capacitive sensor operates by detecting changes to the electrical field in the area around its active zone. If the capacitor plate behind the switching surface is supplied with current, an electric field is generated which reacts to changes in capacitance caused by an approaching object. In this way, measurement variables which are interesting from a production-related point of view (such as fill levels or distances) can be transmitted to the control system.

Capacitive proximity switches are contactless sensors which are free from wear. This means that the detection process itself has no effect whatsoever on the product. Furthermore, because there are no mechanical loads, the life expectancy of the sensor is completely unaffected by its switching frequency. Capacitive sensors are also immune to electromagnetic influences as well as to interference and pollutants in the air. They are therefore ideal for applications in contaminated and dusty environments where other sensors would be susceptible to interference.

The installation situation determines the version used

Basically, the ability of a sensor to detect an object is primarily determined by the size of the object, the dielectric constant and the distance to the active surface. Temperature-related influences as well as the speed of the measurement object also play a role. The installation situation often differs depending on the application. For this reason, the capacitive sensors from Leuze electronic are available in two versions – embedded and non-embedded. Embedded sensors with a linear electrical field scan at a distance and, if required, can also scan through a non-metallic barrier of up to 4mm thick, e.g. wafers, components, cardboard, plastic blocks or stacks of paper. They are even suitable for solids with a low dielectric constant, liquids and granulates. Non-embedded designs with a spherical electrical field, however, are predominantly used as contact sensors, i.e. their active surface comes into direct contact with the object to be scanned. Up to a certain point, material stuck to the active surface does not impair sensor performance. Like the embedded variants, the non-embedded designs are also suitable for e.g. the detection of bulk material and liquids. The only difference is that the non-embedded sensor can make direct contact with the material to be detected. The capacitive proximity switches are available in cylindrical and cubic form. Cylindrical designs are particularly suitable for completeness monitoring in the packaging industry and for detection in rough and soiled environments. Owing to their shape, cubic sensors can be attached to, for example, the outside of containers, thereby enabling the reliable monitoring of fill levels or leaks.

The capacitive proximity switches in numerous variants extend the existing portfolio of optoelectronic and inductive switches from Leuze electronic. They provide users with customized complete solutions for virtually all detection requirements in automation from a single source – including the matching accessories. This ranges from cables in various versions to mounting clamps and quick-change adapters.

Author

Martina Schili

Martina Schili

Corporate Communications

Corporate Communications