www.magazine-industry-usa.com

20

'26

Written on Modified on

Allied Vision Line-Scan Camera Targets High-Speed Sorting

A multi-line CMOS imaging platform enables continuous inspection and identification across logistics, postal and industrial automation workflows.

www.alliedvision.com

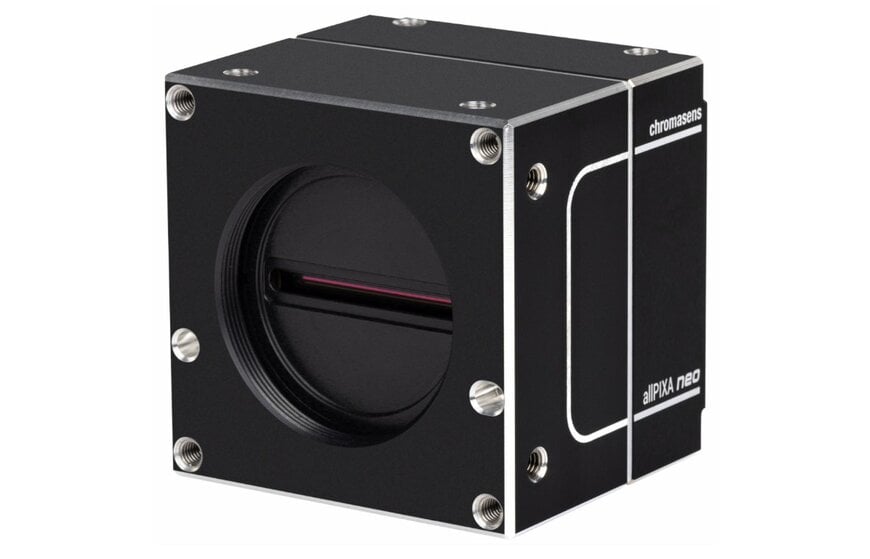

High-throughput conveyor systems rely on precise imaging to read codes, identify objects and prevent routing errors in automated handling processes. In this context, Allied Vision introduced the allPIXA neo 6k 10GigE line-scan camera for automated sorting and inspection environments.

Multi-line imaging for continuous throughput

The camera integrates a CMOS multispectral sensor with 6144 pixels across four lines and a 5 μm × 5 μm pixel size. It operates at up to 105 kHz in colour mode and 300 kHz in monochrome, enabling continuous capture on fast-moving conveyors.

Simultaneous acquisition of four lines allows a collection of colour images alongside an additional monochrome channel in a single pass. This reduces rescanning requirements in logistics facilities handling large item volumes, where unread barcodes or misidentified objects directly affect operational efficiency within a digital supply chain.

Data transfer and synchronization on standard networks

Image transmission uses a 10 GigE (RJ45) interface with Power over Ethernet support, providing high-bandwidth transfer through standard Ethernet infrastructure. The design avoids dedicated cabling typically associated with proprietary vision links.

Pixel-accurate triggering and multi-camera synchronisation maintain geometric consistency across wide conveyor belts. GenICam and GigE Vision compliance allows integration with existing vision software without vendor-specific interfaces.

Sorting and inspection use cases

The allPIXA neo 6k supports applications including postal sorting, parcel routing, warehouse automation, and quality inspection in food and pharmaceutical production. High-speed acquisition combined with multispectral data capture enables identification and classification tasks in conveyor-based systems operating continuously.

www.alliedvision.com