NORD Enhances Efficiency with New Digital Twin and Simulation Capabilities

NORD’s new digital twin and virtual commissioning technology significantly reduces the system development process from planning to commissioning.

www.nord.com

Since the introduction of the Functional Mock-up Interface (FMI) technical standard in 2010, it has become increasingly common to work with simulation models in system planning. Global drive systems manufacturer, NORD DRIVESYSTEMS, also utilizes data-based simulations for the development of components and drive solutions and as of recently, to create digital twins for system development. This innovative technology allows engineers to verify early in the planning process whether the drive concept is suitable for the system, even complex systems, significantly reducing the project timeline and achieving greater efficiency and availability.

Virtual commissioning is done via the myNORD Online Customer Portal. Users configure drive systems for their requirements as usual, selecting features such as performance, mounting options, or outputs. Once they are done with their selection, they can request a simulation model for the fully configured drive system. This process was developed by NORD in cooperation with machineering GmbH & Co. KG, a software company in Munich specializing in virtual commissioning.

One main advantage of digital twins is the significantly faster availability of the entire system. Models from myNORD are inserted into a simulated system, enabling extensive testing before products are ordered and assembled. If adjustments are needed, they can be easily implemented based on the data, with errors being remedied in the early stages of development to avoid potential damage and system downtime later. After the virtual drive system has been tested and validated by the customer, NORD will manufacture and deliver the physical solution. Actual commissioning can be done quickly since the drives are already functionally integrated into the control system. The overall process from configuration to commissioning is reduced from several months to only a few weeks.

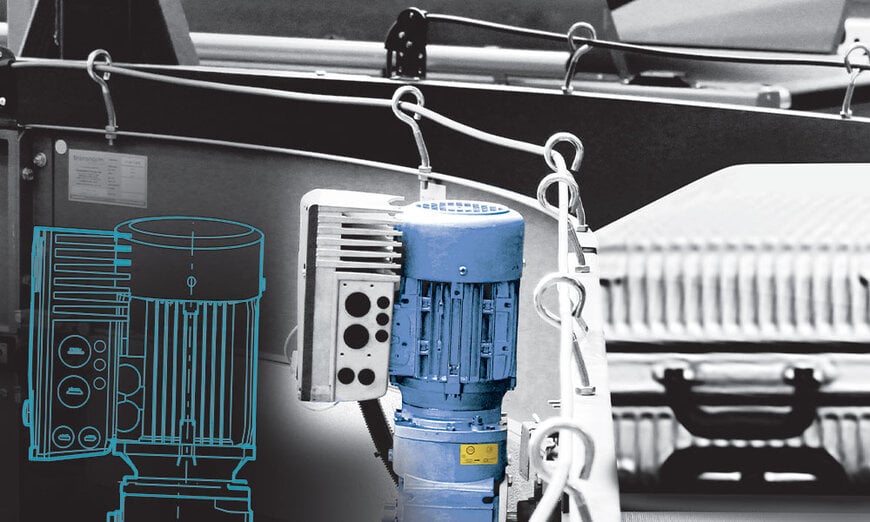

Virtual commissioning is especially beneficial for technically demanding solutions as many issues can be worked out far in advance. That’s why NORD’s primary focus for this initial phase of simulation models focuses on components that play a decisive role in automating production processes such as their range of high-efficiency synchronous motors as well as the corresponding gear units and variable frequency drives. Future simulation models will gradually become available for other NORD product areas.

www.nord.com