www.magazine-industry-usa.com

30

'26

Written on Modified on

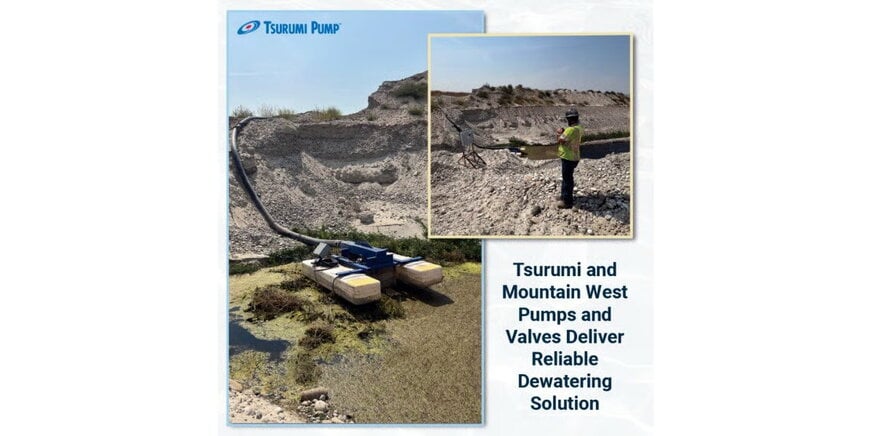

Tsurumi Pump Partners with MWST for Idaho Construction Dewatering Success

Idaho Material Company achieved zero pump failures and lower power costs after switching to Tsurumi's high-volume submersible pump solution, recommended and installed by Mountain West Pumps and Valves.

www.tsurumipump.com

When an Idaho construction materials producer sought a more reliable and cost-effective method to manage water accumulation at a quarry operation, a submersible dewatering system incorporating advanced pump technology delivered marked improvements in uptime, power consumption and maintenance simplicity.

Challenges with Traditional Surface Pumps

The site had relied on conventional centrifugal pumps mounted above the waterline. These units presented several limitations: they were prone to premature wear in abrasive quarry runoff, their motors were vulnerable to moisture exposure, and their operational efficiency was constrained by the inherent design of non-submersible systems. Surface pumps typically require additional infrastructure to keep motors dry and often incur higher energy consumption because they operate outside the pumped fluid, leading to heat and efficiency losses.

In this project, the combination of high running costs, the need for frequent maintenance and the complexity of keeping surface-mounted motors dry prompted a reassessment of the dewatering approach.

Submersible High-Volume Pumping for Harsh Conditions

The site assessment recommended replacing the surface pumps with a submersible high-volume dewatering pump from Tsurumi’s KRS Series, specifically the KRS-811 model, known for its heavy-duty capabilities tailored to construction and quarry environments. Unlike the previous equipment, the submersible design allowed the pump to operate fully immersed in water. Submersible pumps of this class are engineered with rugged cast iron construction and flow-through cooling that maintains motor performance even when submerged, reducing the thermal stress that can limit the duty cycle of surface units.

The conversion to submersible operation also simplified site infrastructure. By eliminating the need for elaborate above-waterline mounting and motor protection, the dewatering system could be installed directly in the pit or barge without complex housing; this not only reduced installation labor but also minimized equipment footprint on the site.

To support consistent performance and optimize electrical usage, the system integrated variable frequency drive (VFD) panels. VFDs regulate motor speed to match fluid load, which lowers energy draw during periods of reduced water inflow and extends mechanical life through softer starts and controlled acceleration. In contrast, fixed-speed surface pumps often run at full capacity irrespective of actual demand, driving up energy costs.

Operational Results and Competitor Comparison

After installation, the submersible system demonstrated several measurable improvements over the previously installed centrifugal pumps. Operating records showed zero unplanned pump failures, indicating enhanced mechanical robustness in an abrasive, wet environment. The use of a fully submerged pump also translated into lower total energy consumption; submersible motors benefit from direct fluid cooling and reduced mechanical losses, which competitive surface systems cannot match without additional cooling apparatus.

Furthermore, the transition to a high-volume submersible model extended the duty cycle—the period during which the pump can run continuously without overheating or needing service. This is a critical performance metric in construction dewatering, where intermittent operation and frequent stops increase wear and maintenance overhead. Compared to the legacy surface pumps, the newer submersible solution required fewer interventions and offered greater flexibility in managing water levels across changing site conditions.

Implications for Construction Dewatering Practice

This project illustrates key advantages of modern submersible dewatering pump technology in heavy construction and quarry operations. Submersible designs inherently place the hydraulic machinery and motor in the pumped fluid, which enhances cooling and protects critical components from environmental exposure. When combined with smart control systems such as VFDs, these pumps can deliver improved energy efficiency and extended service life in applications where traditional surface pumps struggle.

www.tsurumipump.com