www.magazine-industry-usa.com

27

'26

Written on Modified on

Emerson Expands AI-Driven Asset Performance Management

Software update supports scalable predictive maintenance and enterprise reliability across industrial operations.

www.emerson.com

Industrial facilities are under pressure to reduce unplanned downtime while extending asset life and controlling maintenance costs. Asset Performance Management (APM) platforms address this by combining condition monitoring, analytics, and maintenance workflows. Within this context, Emerson has released an updated version of Aspen Mtell® to extend AI-based failure prediction across broader asset fleets.

From condition monitoring to predictive maintenance at scale

The update focuses on helping organizations move from basic asset health monitoring toward predictive maintenance programs that operate consistently across multiple sites and asset types. Industry- and asset-specific templates are used to standardize deployments, allowing monitoring models to be configured more quickly and replicated across similar equipment classes.

This approach supports gradual scaling: initial monitoring establishes baseline performance data, after which AI-driven analytics are applied to identify early failure patterns. Such staged deployment reduces the need for large, upfront engineering efforts and supports measurable returns as coverage expands.

AI models prioritize risk and maintenance action

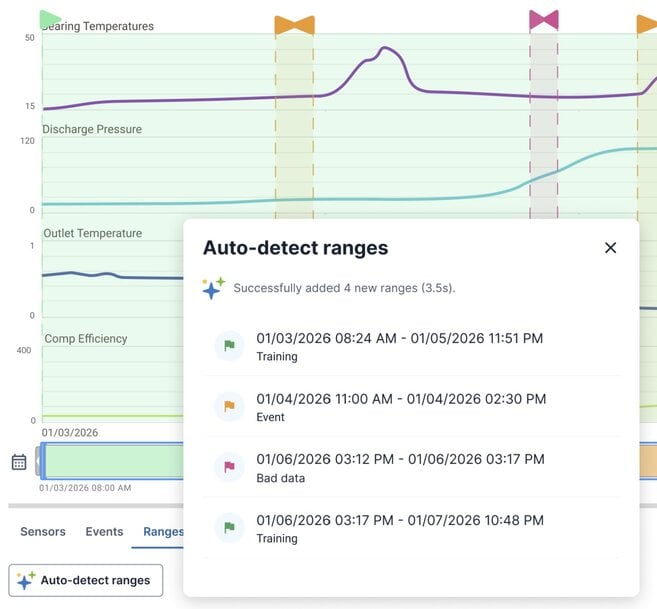

A core feature of the new Aspen Mtell release is automated alert handling. AI-based analytics evaluate incoming condition data and group alerts by severity, operational risk, and historical behavior. This reduces the volume of unfiltered notifications typically associated with condition monitoring systems.

The platform also embeds failure mode and effects analysis (FMEA) logic within its diagnostics. When a developing fault is detected, the system links patterns in sensor and process data to likely failure modes and suggests corrective actions. This shortens the time between detection and maintenance response and helps standardize decision-making across maintenance teams.

Integration with vibration and device monitoring

The updated system connects directly with Emerson’s AMS Machine Works and AMS Device Manager platforms, which provide vibration and device health data. This integration brings rotating equipment diagnostics, field device condition data, and higher-level analytics into a shared reliability environment.

Combining these data sources allows correlations between process conditions, mechanical vibration signatures, and instrumentation performance. Such cross-domain analysis supports earlier identification of issues such as bearing wear, imbalance, or valve degradation that may not be visible through a single monitoring method.

Linking reliability insights to enterprise workflows

Beyond detection, the platform is designed to feed actionable insights into enterprise asset management and enterprise resource planning systems. Maintenance recommendations generated by the analytics can be transferred into existing work order and planning workflows, supporting closed-loop maintenance execution.

This integration connects predictive analytics with scheduling, spare parts planning, and maintenance history, aligning digital reliability tools with established operational processes. Within a broader industrial AI and predictive maintenance strategy, this linkage is intended to ensure that identified risks translate into timely, documented maintenance actions rather than remaining isolated within monitoring dashboards.

Continuous improvement through data-driven reliability

By combining standardized deployment templates, AI-based diagnostics, and enterprise system integration, the updated Aspen Mtell platform is positioned as a tool for ongoing reliability improvement. As more operational and failure data are accumulated, models can be refined, enabling progressively earlier and more accurate fault detection across diverse industrial assets.

www.emerson.com