Experience NORD’s Reliable, High-Performance Grain Solutions at GEAPS

NORD returns to GEAPS Exchange February 21 – 24, 2026 at the Kansas City Convention Center.

www.nord.com

The grain industry’s largest show, GEAPS Exchange, returns to the Kansas City Convention Center February 21 – 24, 2026 and NORD DRIVESYSTEMS will be in attendance at Booth 3526. NORD’s modular product system of gear units, heavy-duty industrial gear units, AC electric motors, and electronic control products for centralized and decentralized systems are highly configurable with over 20,000,000 unique standard options, offering a solution for nearly every application. Their solutions for the grain industry focus on robustness, versatility, and reliability while still delivering high performance and long service life. NORD’s specialized drive solutions meet the requirements of most grain production, processing, and packaging applications such as bucket elevators, drag and belt conveyors, screw conveyors, rotary valves, silo reclaimers, slide gates, feeders, and more.

NORD will be showcasing these featured products at GEAPS Exchange Booth 3526:

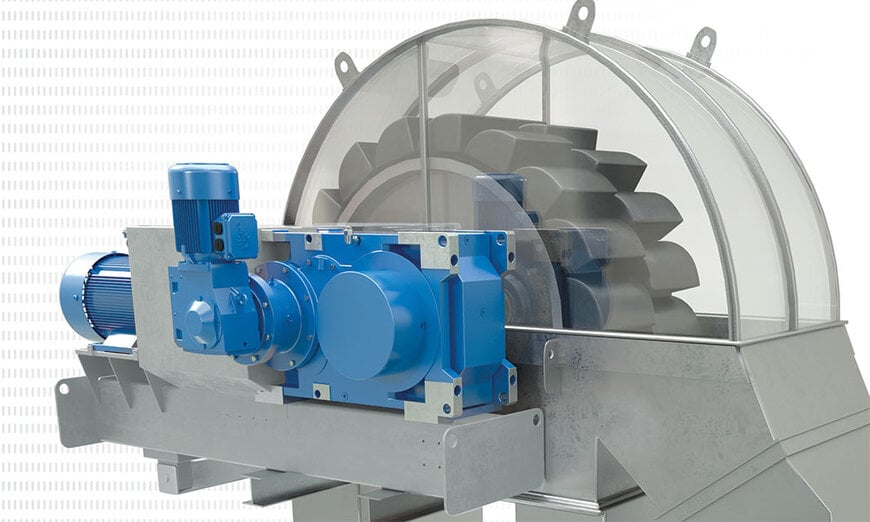

MAXXDRIVE® Industrial Gear Units

MAXXDRIVE industrial gear units are ideal for heavy-duty grain applications such as bucket elevators, belt conveyors, drag conveyors, chain conveyors or en masse conveyors, drums, and more thanks to their high output torques up to 2,495,900 lb-in. The compact XC series is available in right-angle and parallel shaft designs with 11 case sizes, extensive input options, mounting options, and add-on modules for optimal application selection. Special sealing solutions, backstops, fluid couplings, and swing bases are available to meet the unique needs of applications such as bucket elevators while other specialized options for the grain industry include cooling and heating options for temperature management, safety features to protect operators and equipment, as well as reinforced bearing designs for high axial and radial loads.

MAXXDRIVE XT industrial gear units feature two gear stages and a right-angle, symmetrical design capable of mirror-image installation, greatly reducing the number of replacement gear units required. Their finned housing design helps quickly dissipate heat while an axial fan and air guide covers enhance airflow, preventing the unit from overheating even at maximum power and making them a reliable, robust solution for high-speed applications as well as capable of withstanding fluctuating ambient conditions common in the grain industry.

MAXXDRIVE industrial gear units also have the option of adding a Grain Endurance Package, a comprehensive set of protective measures that optimize performance, maintain reliability, simplify maintenance, and extend service life of the drive components in harsh grain environments. The predominant elements include a drying agent filter, oil sampling port, filter cart quick disconnects, oil level inspection sight glass, and an oil drain valve.

UNICASE™ Helical Bevel Gear Units

UNICASE helical bevel gear units are made from a robust, single-piece housing that offers long-lasting gearing, high axial and radial load capacity, minimum backlash, and a long service life for applications such as drag and chain conveyors, rotary feeders, and small belt conveyors. Thanks to 11 case sizes with a torque range up to 442,500 lb-in. and a variety of shaft and mounting options including the GRIPMAXX keyless bushing system, these gear units are highly adaptable to specific application needs. Various heavy duty bearing and spread bearing/flange mount designs additionally provide increased load capacity and extended service life.

Electric Motors

Electric motors from NORD are manufactured in-house for short lead times and meet all common global efficiency regulations and standards. The portfolio includes a wide range of both synchronous and asynchronous motors with efficiency ranging from IE1 all the way up to IE5+ ultra-premium efficiency. They are highly customizable with options including brakes, IP66 protection, encoders, external cooling fans, thermal protection, and more. Dust explosion protected motors and gas explosion protected motors are also available for hazardous locations.

Screw Conveyor Package

The NORD Screw Conveyor Package offers a compact, cost-effective alternative to traditional screw conveyor drives for UNICASE parallel shaft gear units and UNICASE helical bevel gear units. The innovative design utilizes a directly coupled gear motor or NEMA C-face input that eliminates the need for top motor mounts, pulleys, belts, or guards, enabling a safer, more reliable design that protects technicians, reduces system maintenance, and increases drive performance. An optimized sealing system with QUADRALIP seals assures lubricating oil stays inside the gearbox while contaminants, such as dirt and moisture, stay out. The standard CEMA mounting flange additionally provides versatility for application constraints thanks to multiple bolt patterns while the tapered 3-hole CEMA drive shaft allows for screw pipe misalignment and makes mounting and removal quick and easy.

NORD’s Screw Conveyor Package delivers a compact, energy-efficient solution that is easy to install and maintain thanks to the elimination of top motor mounts, pulleys, and belts.

Find all these solutions and more by visiting NORD at GEAPS Exchange 2026.

www.nord.com