Challenges to Consider When Selecting a Feeder

By Ryan Coburn, Technical Sales Specialist, and Clark Wright, Technical Development Engineer, Hapman.

hapman.com

Inside PosiPro® with agitator

Moving dry bulk materials in industrial environments presents unique challenges, particularly when dealing with products that are abrasive, sticky, or prone to clumping. These material characteristics can disrupt operations, reduce efficiency, and accelerate equipment wear. Selecting the right feeder is therefore essential to maintain consistent performance, protect equipment, and minimize downtime.

Dosing feeders are engineered to address many of these issues. Understanding the typical challenges associated with difficult materials, and the feeder features that help overcome them, allows operators to improve process reliability, efficiency, and safety.

Common challenges when handling difficult materials

Clumping and material bridging

Materials such as flour, cocoa powder, and sugar can clump or bridge inside hoppers, especially when exposed to moisture or compaction. This disrupts material flow, leading to inconsistent feeding and process interruptions. In food, chemical, and similar industries, such variability can directly affect product quality and throughput.

Inconsistent material flow

Uniform feed rates are critical in most production processes. Materials with variable density or adhesive properties can cause blockages or surging, complicating downstream operations and reducing overall efficiency.

Abrasive and corrosive wear

Abrasive or corrosive materials accelerate wear on feeder components and increase contamination risk. This is especially problematic in industries like pharmaceuticals and food processing, where hygiene and material integrity are essential.

Maintenance and safety concerns

Frequent cleaning and maintenance can increase downtime and expose operators to safety risks. Traditional feeder designs may require extensive disassembly, making it challenging to balance productivity, safety, and regulatory compliance.

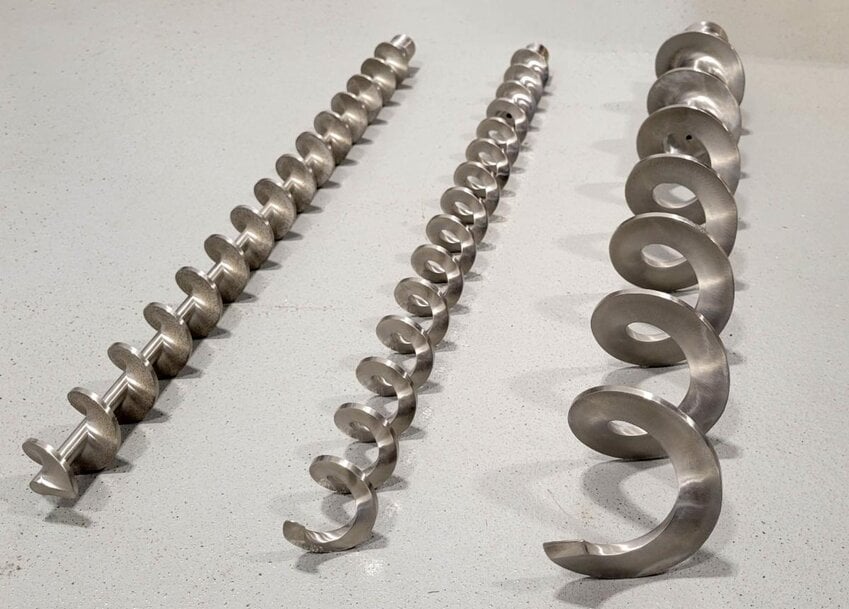

Screws

Feeder features that address these challenges

Internal agitation systems

An internal agitator helps break up clumps and prevent bridging. Independent agitation motors and adjustable speeds allow the feeder to adapt to different material behaviors, ensuring consistent flow into the screw.

Independent motor control

Separate drives for the screw and agitator provide precise control over feed rates. This flexibility allows operators to fine-tune performance for specific materials, avoiding over-agitation and improving consistency.

Stainless steel construction

Using stainless steel, particularly grades 304 or 316, improves corrosion resistance and simplifies cleaning. This durability supports abrasive applications while meeting hygiene requirements in sensitive industries.

Volumetric and gravimetric options

Volumetric feeders offer reliable performance for many applications, while gravimetric systems provide weight-based accuracy where precise dosing is critical, such as in pharmaceutical or specialty chemical production.

Enhanced safety features

Modern dosing feeders incorporate bolt-on safety components such as nozzles and bar grates. These features protect operators, reduce maintenance complexity, and support compliance without sacrificing efficiency.

Customization and flexibility

Interchangeable screws, extension hoppers, and other configurable components allow a single feeder platform to handle a wide range of material properties and process requirements.

PosiPro® with hopper

Best practices for reliable feeder operation

- Prevent material buildup: Regularly clear residual material to avoid clogging and contamination.

- Test materials: Evaluating bulk density, moisture, and flow characteristics helps optimize feeder configuration.

- Perform routine maintenance: Scheduled inspections and cleaning extend equipment life and reduce unplanned downtime.

The Hapman PosiPro® dosing feeder

The Hapman PosiPro® dosing feeder is designed to address the challenges of handling difficult dry bulk materials. Features such as independent motor controls and robust internal agitation promote consistent flow across a wide range of applications. Stainless steel construction enhances durability and cleanability, supporting hygienic operations.

Optional conical extension hoppers improve material flow and reduce buildup, while bolt-on safety features simplify maintenance and protect operators. Combined with Hapman’s material testing services, the PosiPro® can be configured to meet specific process demands.

For manufacturers seeking reliable handling of challenging materials, the Hapman PosiPro® dosing feeder provides a balance of precision, durability, and safety, helping improve efficiency and support long-term operational success.

www.hapman.com