www.magazine-industry-usa.com

10

'17

Written on Modified on

Where chips are flying.. .

... tool holding plays an important role in process reliability

The successful Pilatus Turboprop multi-role aircraft PC12: like all other Pilatus aircrafts, it mainly consists of aluminum structural components.

Picture: Pilatus Aircraft

In 2016 Pilatus Aircraft Ltd installed new manufacturing systems for machining structural parts made of aluminum. In order to achieve the desired surface quality and precision during high speed milling operations, the aircraft manufacturer continuously relies on the solutions provided by HAIMER: a large selection of tool holders and the corresponding shrinking and balancing machines.

Whenever someone in the precision machining industry talks about flying, one thing is typically brought up: chips. This also applies to Pilatus Aircraft Ltd, the only Swiss aircraft manufacturer. At the headquarters in Stans, Switzerland, everything generally revolves around the topic "flying", but machining structural parts also plays an important role. In 2016 Pilatus invested in a completely modernized volume-machining system in order to further improve the quality and efficiency of the production. Core elements of the enhanced production are two new flexible manufacturing systems that are run with full automation and guarantee the highest quality in a stable process.

Walter Duss, Director Milling, points out that fine-balanced tools are absolutely necessary: "Only the high balancing grade of the complete tool assembly - balanced on a HAIMER balancing machine - together with HAIMER tool holders can guarantee vibration-free machining and surfaces without any chatter marks. Furthermore, the high run-out accuracy significantly increases the lifetime of the spindle and tools."

According to the experience of Patrik Odermatt, Team Leader Mechanical Processing and responsible for the internal division of tools at Pilatus, high quality tool holders that offer long-term stability and run-out accuracy definitely pay off. It is for this reason that he has been working with HAIMER in Igenhausen for many years. He uses HAIMER Shrink Fit Chucks and High-Precision Collet Chucks together with the corresponding presetting, shrinking and balancing machines that are available at the Pilatus toolshop which serves as their internal tool management service center. "Regarding such topics as quality, price-performance ratio, consultation and support, our experience with HAIMER is very positive" Patrik Odermatt explains. "That's why we made the decision to continuously and solely rely on tool holding technology from HAIMER when it comes to our new manufacturing system. We exclusively use tools that are clamped into HAIMER Standard Shrink Fit Chucks, ultra-short and long Power Shrink Chucks as well as Power Mini Shrink Chucks, Power Collet Chucks and special Face Mill Arbors.”

Since Pilatus is working with many different parts that are extremely thin with wall thicknesses ≤ 1.2 mm and deep pockets, the wide range of HAIMER tool holders was an important consideration. Also HAIMER has shown flexibility regarding the spindle interface: for the new manufacturing systems a special HSK-A 63/80 tool holder was necessary. After close cooperation with Pilatus, HAIMER developed a program for this interface and added it to its standard delivery portfolio.

HAIMER also proves to be innovation-driven with its patent pending mechanical locking Data-Lock system that fixes the RIFD data carrier onto the tool holder. Pilatus uses this solution to ensure that even at the highest rpm the data carriers are securely fixed and cannot separate from the tool holder.

According to tool expert Odermatt, one of the greatest advantages of working with HAIMER is the fact that you can get all tool holding technology from one single source. “For every HAIMER Shrink Fit Chuck the required parameters are already integrated into the shrinking machines,” stated Odermatt. “The performance and heating time are ideal and guarantee process-reliable shrinking at the push of a button. And balancing is also easy to perform.”

User contact:

Pilatus Flugzeugwerke AG

Postfach 992

6371 Stans, Schweiz

Telefon: +41 41 619 61 11

Fax: +41 41 610 92 30

http://www.pilatus-aircraft.com

This email address is being protected from spambots. You need JavaScript enabled to view it.

Video material:

On the HAIMER YouTube channel you can also find a success video about the application report with Pilatus.

You are welcome to use the video for your online edition or website.

https://www.youtube.com/watch?v=PM7FmJp4tIg

B02_HAIMER_Pilatus_B7A0098

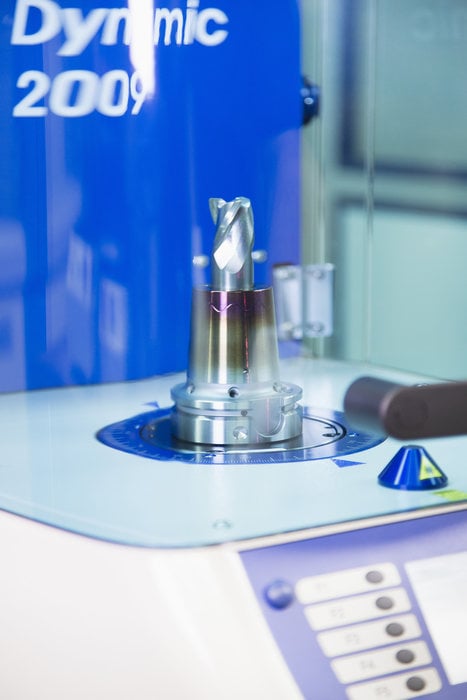

The new flexible manufacturing systems at Pilatus in Stans are regularly equipped with HAIMER tool holders (on the picture: shrink fit chuck with HSK-A 63/80 interface) pictures: HAIMER

B03_HAIMER_Pilatus_7962 / B03_HAIMER_Pilatus_B7A0338

Spar strap for the multi role aircraft PC-12: 380kg raw part is transformed into a 35kg finished part.

B04_HAIMER_Pilatus_7966

Typical structural components with a cutting grade of more than 95%.

B05_HAIMER_Pilatus_7954

Balanced tools are available in the toolshop and can be used at any time.

B06_HAIMER_Pilatus_B7A9283

Easy and repeatable shrinking procedure: for each HAIMER Shrink Fit Chuck the required parameters are already integrated into the HAIMER Power Clamp Premium.

B07_HAIMER_Pilatus_B7A9578

With the HAIMER Tool Dynamic Comfort balancing machine, the balancing grade of the complete tool assembly is inspected and corrected at G2.5 at 33,000 rpm.

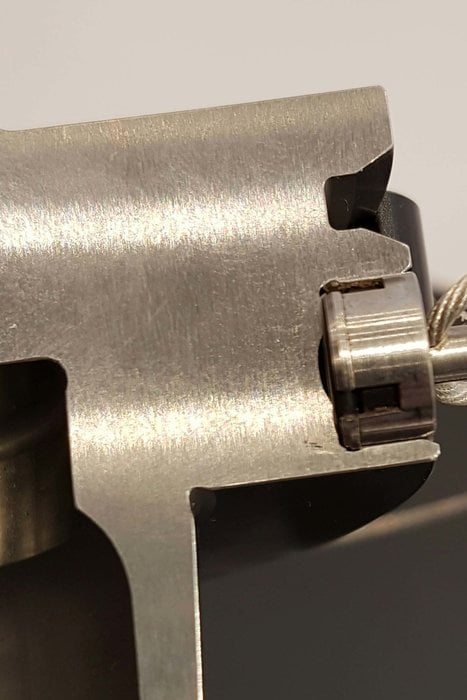

B08_HAIMER_Pilatus_B7A9237 / B08_HAIMER_Pilatus_Data-LockB1 / B08_HAIMER_Pilatus_Data-LockB2

For the RFID Chip (data carrier with which you can save important tool data) HAIMER offers a mechanical locking system that securely fixes the chip onto the tool holder (even at high rpm) without influencing the reading and writing quality of the RFID Chip.

B09_HAIMER_Pilatus_7931

Patrik Odermatt, Team Leader Mechanical Processing, and Walter Duss, Director Milling, are of the same opinion: "HAIMER is the ideal partner for us and provides us with tool holders, shrinking and balancing technology with easy to handle machines. Our experience has told us that the quality of the products is continuously high."

B10_HAIMER_Pilatus_B7A9699

Patrik Odermatt (left) and Walter Duss (middle) of the aircraft manufacturer Pilatus and Tobias Völker, tool holding specialist at HAIMER are pleased about their successful cooperation in the field of volume metal cutting.