www.magazine-industry-usa.com

06

'25

Written on Modified on

How Automation is Redefining the Modern Supply Chain

From manual to autonomous, the modern supply chain is evolving and is not just automated, but intelligent, adaptive, and alive.

Amidst all the digitalisation witnessed in the field of manufacturing, it is the supply chain that has perhaps experienced the most dramatic transformation in recent years. What was once considered a rather dull and mostly unseen logistical operation, the supply chain has today become a strategic backbone of global industry. Yet it took a global pandemic to demonstrate how fragile this vital link was in reality, causing massive disruption globally as most operations were affected by the lockdown, as all sourcing strategies went haywire.

In the new scheme of things, automation has taken centre stage in the evolution of the supply chain. From AI-driven demand forecasting to warehouse robots, and digital twins to end-to-end data visibility, automation is not just about improving efficiency. It is also redefining resilience, agility, and sustainability. The ability to adapt quickly to disruptions, anticipate demand, and optimise flow is no longer optional – it has become a competitive necessity.

As one logistics automation expert explains, ‘The supply chain is no longer about moving goods; it’s about moving information just as intelligently’. This convergence of operational technology (OT) and information technology (IT) marks the true evolution – from manual coordination to digitally autonomous ecosystems that are capable of self-correction and predictive decision-making.

For engineers, plant managers, and automation professionals, this shift represents both a challenge and an opportunity. The integration of robotics, industrial IoT (IIoT), AI, and advanced analytics is transforming not only how materials move, but how entire industrial ecosystems collaborate.

Traditional vs. Modern supply chains

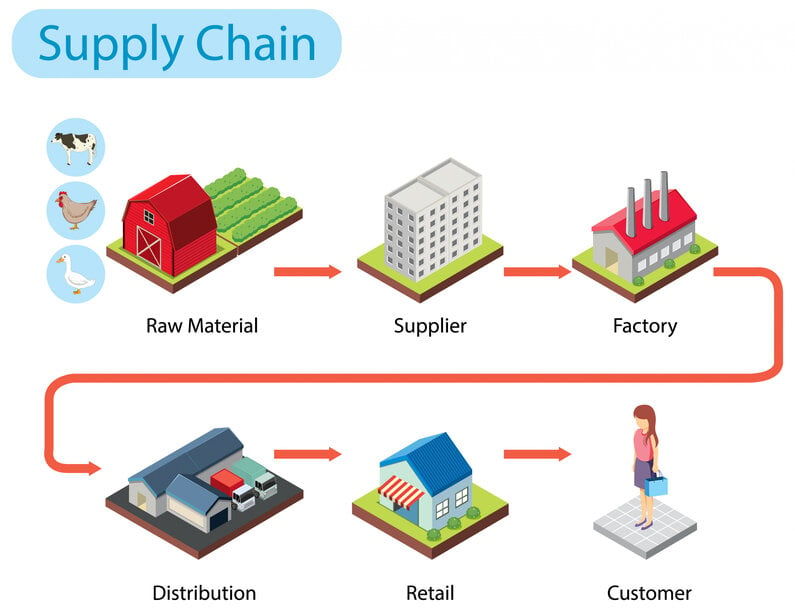

To appreciate how far automation has impacted modern supply chains, it would be interesting to recall the characteristics of the traditional supply chain. Historically, supply chains were linear and operated in siloes: raw materials moved through a sequence of suppliers, manufacturers, distributors, and retailers. Each node operated with its own systems, with data exchanged via spreadsheets, phone calls, or manual reports.

Such models worked reasonably well when demand was stable, product life cycles were long, and logistics networks were local or regional, but things have changed drastically now. The onset of globalisation, shorter product cycles, and rising customer expectations have exposed the weaknesses of this linear design. Manual processes can no longer keep up with growing complexity or the need for real-time visibility.

The result was often information latency – by the time a problem was identified, it was already too late to act. Excess inventory, stockouts, and inefficiencies were accepted as the cost of doing business. The traditional ‘forecast and push’ model – where production was based on anticipated demand rather than real-time data – proved increasingly unreliable.

On the other hand, modern supply chains are dynamic, interconnected, and data-driven. They rely on automation technologies to capture, analyse, and act on data across every node in the network. Visibility is now end-to-end, from suppliers to customers, enabling agile responses to changing conditions. Instead of static planning, companies employ adaptive, automated workflows powered by advanced analytics, machine learning, and real-time IoT data.

Needless to say, this transformation did not happen overnight – it began with the first wave of digitalisation.

The early digitalisation: ERP, barcode, and basic IT

Automation of the modern supply chain began in the late 1980s and early 1990s with the rise of enterprise resource planning (ERP) systems, barcoding, and early warehouse management systems (WMS). These technologies marked the initial effort to bring structure and data-driven control to logistics and manufacturing operations.

ERP systems unified disparate functions – procurement, production, inventory, and finance – into a single digital backbone. This improved coordination and data accuracy, giving managers the ability to track materials and costs more effectively. Barcodes and scanners brought speed and reliability to inventory management, dramatically reducing human error.

However, these were mere patches of automation on a large canvas, not full integration. The systems depended on manual inputs and batch processing rather than real-time data flows. Decisions remained largely reactive, based on historical data rather than predictive insights. Yet, these foundational tools built the digital discipline that made the next revolution possible: the connected, intelligent supply chain of the Industry 4.0 era.

Industry 4.0: The real shift begins

While early digital tools improved basic coordination, the true transformation of supply chains began with the advent of Industry 4.0 – the convergence of connectivity, data, automation, and intelligence across every node of the value chain.

Unlike previous industrial revolutions, which focused on mechanisation or electrification, Industry 4.0 is about integration. Machines, systems, people, and processes are all connected through a digital fabric, enabling information to flow seamlessly from the factory floor to the boardroom – and even to the end customer.

At the core of this shift is the Industrial Internet of Things (IIoT). Sensors embedded in equipment, conveyors, pallets, and even packaging continuously capture data: location, temperature, machine status, energy usage, and more. This data feeds into cloud platforms, MES (Manufacturing Execution Systems), WMS (Warehouse Management Systems), and TMS (Transportation Management Systems), creating real-time visibility across the supply chain.

But connectivity alone isn’t the breakthrough – it’s what automation does with the data.

Industry 4.0 enables:

- Predictive maintenance: Machines alert operators before failure.

- Dynamic scheduling: Production adjusts based on real-time demand.

- Automated replenishment: Inventory restocks itself through system triggers.

- End-to-end traceability: Every item can be tracked throughout its life cycle.

This is where supply chains begin to shift from fixed sequences to adaptive networks. The once rigid division between manufacturing, logistics, and distribution fades away. Instead, supply chains evolve into digitally synchronised ecosystems, leveraging shared data and automated decision-making to optimise performance. As one manufacturing CIO observed, ‘You cannot manage complexity with spreadsheets. You need systems that think, learn, and act faster than humans can’.

This need for speed and agility ushered in the next major leap: intelligent automation.

The role of automation in big transformation

Automation in supply chains is no longer limited to conveyor belts or basic robotics. Today, it spans physical automation, process automation, and cognitive automation, creating a layered system of efficiency and intelligence.

The core technologies that have reshaped the supply chain landscape may be summarised as:

1. Robotics, cobots, and autonomous vehicles

Modern warehouses and factories are increasingly populated by robots, cobots (collaborative robots), and autonomous mobile robots (AMRs/AGVs). Picking and packing robots reduce human labour in repetitive tasks. Cobots work alongside human operators, enhancing productivity and safety. AMRs and AGVs navigate warehouse floors without fixed tracks, using sensors and AI to adapt to dynamic environments.

For example, Amazon reportedly operates over 750,000 robots in its fulfillment centres – working in harmony with humans to speed up order processing. This hybrid approach reduces travel time, optimises storage, and allows 24/7 operation.

2. AI and Machine learning: The supply chain brain

If robotics is the muscle of automation, AI is the brain. AI-powered systems analyse massive datasets across demand signals, supplier performance, transportation conditions, and even weather patterns to make smarter decisions. Key applications include:

This need for speed and agility ushered in the next major leap: intelligent automation.

The role of automation in big transformation

Automation in supply chains is no longer limited to conveyor belts or basic robotics. Today, it spans physical automation, process automation, and cognitive automation, creating a layered system of efficiency and intelligence.

The core technologies that have reshaped the supply chain landscape may be summarised as:

1. Robotics, cobots, and autonomous vehicles

Modern warehouses and factories are increasingly populated by robots, cobots (collaborative robots), and autonomous mobile robots (AMRs/AGVs). Picking and packing robots reduce human labour in repetitive tasks. Cobots work alongside human operators, enhancing productivity and safety. AMRs and AGVs navigate warehouse floors without fixed tracks, using sensors and AI to adapt to dynamic environments.

For example, Amazon reportedly operates over 750,000 robots in its fulfillment centres – working in harmony with humans to speed up order processing. This hybrid approach reduces travel time, optimises storage, and allows 24/7 operation.

2. AI and Machine learning: The supply chain brain

If robotics is the muscle of automation, AI is the brain. AI-powered systems analyse massive datasets across demand signals, supplier performance, transportation conditions, and even weather patterns to make smarter decisions. Key applications include:

- Demand forecasting

- Inventory optimisation

- Dynamic routing, and

- Risk prediction.

According to McKinsey, AI-enabled supply chains can reduce forecasting errors by up to 50%, leading to 65% lower lost sales and 20% lower inventory costs.

3. RPA (Robotic Process Automation): Automating the back office

Not all supply chain automation is physical. Robotic process automation (RPA) handles repetitive digital tasks such as:

3. RPA (Robotic Process Automation): Automating the back office

Not all supply chain automation is physical. Robotic process automation (RPA) handles repetitive digital tasks such as:

- Order processing

- Invoice matching

- Purchase requisitions, and

- Data entry across ERP/WMS/CRM systems.

By automating these workflows, companies eliminate manual errors, speed up approvals, and free staff for higher-value work.

4. Digital twins & simulation

A digital twin is a virtual model of a supply chain, facility, or process that mirrors real-world conditions. Using real-time data, digital twins allow companies to simulate ‘what if’ scenarios before executing in the physical world. For example, what happens if a supplier shuts down? How will a 20% demand spike affect production? Which layout maximises warehouse throughput?

This predictive capability transforms supply chains from reactive to proactive.

5. Cloud & edge computing: The new digital infrastructure

Automation requires computing power and connectivity. Cloud platforms provide centralised data storage and AI capabilities, while edge computing brings real-time processing closer to devices on the shop floor or warehouse.

This hybrid approach ensures:

4. Digital twins & simulation

A digital twin is a virtual model of a supply chain, facility, or process that mirrors real-world conditions. Using real-time data, digital twins allow companies to simulate ‘what if’ scenarios before executing in the physical world. For example, what happens if a supplier shuts down? How will a 20% demand spike affect production? Which layout maximises warehouse throughput?

This predictive capability transforms supply chains from reactive to proactive.

5. Cloud & edge computing: The new digital infrastructure

Automation requires computing power and connectivity. Cloud platforms provide centralised data storage and AI capabilities, while edge computing brings real-time processing closer to devices on the shop floor or warehouse.

This hybrid approach ensures:

- Faster responses

- Lower latency for critical operations

- Scalable storage and analytics, and

- Seamless integration across global networks.

Together, these technologies lay the foundation for the next stage of evolution: the autonomous, self-optimising supply chain.

The rise of the smart, autonomous supply chain

In the most advanced organisations, automation is no longer just about task execution – it’s about decision-making. This is the birth of the smart supply chain.

A smart supply chain has three defining traits:

The rise of the smart, autonomous supply chain

In the most advanced organisations, automation is no longer just about task execution – it’s about decision-making. This is the birth of the smart supply chain.

A smart supply chain has three defining traits:

- Connected – Every asset and process is digitally linked.

- Intelligent – Data is analysed in real time to guide decisions.

- Automated – Actions are executed with minimal human intervention.

Examples in action:

- Self-adjusting production schedules based on live sales data.

- Automated re-routing of shipments to avoid disruption.

- Adaptive warehouse layouts optimised by AI simulations.

- End-to-end visibility dashboards enabling control tower operations.

Today, all major logistics companies use robots, AI, and digital twins to maximise efficiency. Similarly, major manufacturers from automobiles to consumer goods integrate their operations and supply chain systems so tightly that design changes are reflected instantly in production and sourcing. In short, the entire network behaves as a coordinated, intelligent system. As one CTO in automotive manufacturing said, ‘Our supply chain isn’t a process anymore – it’s a living digital organism’.

Not without challenges

While the core technologies and connected operations have indeed facilitated the transition to smart or autonomous supply chains, the transition is not without its share of challenges. Integration is the key to successful execution. It is not enough to have a robot that can pick orders – what is important is to have a robot that syncs with inventory databases, WMS, and transportation schedules in real time, for the experience to become truly transformative. This is an area where many organisations struggle.

What exactly are the challenges?

1. Legacy systems vs Modern platforms: Many manufacturers and logistics providers still rely on decades-old systems that were never designed to communicate externally. Integrating these legacy systems with modern cloud platforms, IoT devices, and AI engines requires significant investment and expertise.

2. Data silos: Supply chains often span multiple departments and external partners – each with their own data formats, rules, and KPIs. Without a single source of truth, automation can only optimise locally, not across the full network.

3. Need for standardisation & APIs: The rise of APIs (Application Programming Interfaces) and standardised communication protocols such as OPC UA and MQTT are making it easier to connect systems. Yet full interoperability remains a work in progress.

4. IT/OT convergence: Traditional manufacturing OT systems were isolated from IT networks for security and reliability. Today, the two worlds must converge to enable end-to-end visibility. This requires bridging cultural as well as technical gaps – IT teams focus on data and security, while OT teams focus on uptime and equipment safety.

5. Cybersecurity: As more devices and systems connect, cyber risks multiply. Supply chains have become prime targets for ransomware and data breaches. Modern automation strategies must include zero-trust architectures, real-time threat monitoring, and secure communication protocols.

The inference is obvious. Automation without integration creates pockets of efficiency. But automation with seamless integration creates strategic advantage.

Supply Chain-as-a-Service

Another major shift in modern supply chains is the move from ownership to access. Instead of building and maintaining every supply chain capability in-house, companies are turning to platform-based models and Supply Chain-as-a-Service (SCaaS).

SCaaS is characterised by the following salient features:

Not without challenges

While the core technologies and connected operations have indeed facilitated the transition to smart or autonomous supply chains, the transition is not without its share of challenges. Integration is the key to successful execution. It is not enough to have a robot that can pick orders – what is important is to have a robot that syncs with inventory databases, WMS, and transportation schedules in real time, for the experience to become truly transformative. This is an area where many organisations struggle.

What exactly are the challenges?

1. Legacy systems vs Modern platforms: Many manufacturers and logistics providers still rely on decades-old systems that were never designed to communicate externally. Integrating these legacy systems with modern cloud platforms, IoT devices, and AI engines requires significant investment and expertise.

2. Data silos: Supply chains often span multiple departments and external partners – each with their own data formats, rules, and KPIs. Without a single source of truth, automation can only optimise locally, not across the full network.

3. Need for standardisation & APIs: The rise of APIs (Application Programming Interfaces) and standardised communication protocols such as OPC UA and MQTT are making it easier to connect systems. Yet full interoperability remains a work in progress.

4. IT/OT convergence: Traditional manufacturing OT systems were isolated from IT networks for security and reliability. Today, the two worlds must converge to enable end-to-end visibility. This requires bridging cultural as well as technical gaps – IT teams focus on data and security, while OT teams focus on uptime and equipment safety.

5. Cybersecurity: As more devices and systems connect, cyber risks multiply. Supply chains have become prime targets for ransomware and data breaches. Modern automation strategies must include zero-trust architectures, real-time threat monitoring, and secure communication protocols.

The inference is obvious. Automation without integration creates pockets of efficiency. But automation with seamless integration creates strategic advantage.

Supply Chain-as-a-Service

Another major shift in modern supply chains is the move from ownership to access. Instead of building and maintaining every supply chain capability in-house, companies are turning to platform-based models and Supply Chain-as-a-Service (SCaaS).

SCaaS is characterised by the following salient features:

- Cloud-based supply chain platforms: Software giants like SAP, Oracle, Microsoft, and Kinaxis now offer integrated cloud platforms that manage planning, logistics, procurement, and analytics. These platforms unify data across the supply chain and enable automation at scale.

- Logistics platforms: Companies like DHL, UPS, Maersk, Flexport, and Amazon offer logistics-as-a-service powered by automation. They provide smart warehousing, route optimisation, customs automation, visibility dashboards, and predictive analytics.

- Control towers: A supply chain control tower offers a central, real-time view of operations across geographies, enabling proactive decisions. When integrated with AI and automation, these control towers become autonomous command centers that can respond to disruptions without human intervention.

- Network-based collaboration: Instead of linear chains, modern supply chains are moving toward multi-enterprise networks – shared digital platforms where suppliers, manufacturers, logistics providers, and customers collaborate in real time.

This ‘platformisation’ of supply chains enables smaller companies to access advanced automation without massive capital investment. It democratises innovation and levels the playing field.

Sustainability & circular supply chains

Sustainability today is no longer a branding exercise – it’s a regulatory and economic imperative. Automation plays a critical role in enabling green, efficient, and circular supply chains.

This is sought to be achieved systematically and methodically, using the tools of technology:

1. Tracking environmental impact: IoT sensors and data platforms track energy usage, emissions, and waste across facilities and transportation networks, helping companies measure and optimise sustainability performance.

2. Reducing waste and inventory: Automation improves demand forecasting, production planning, and inventory control – leading to fewer excess materials and obsolete stock.

3. Optimising routes and loads: AI-based logistics platforms optimise vehicle routes, consolidate loads, and reduce empty miles, lowering fuel consumption and carbon emissions.

4. Reverse logistics and recycling: Circular supply chains require efficient handling of returns, remanufacturing, and recycling. Automation in sorting, inspection, and reverse logistics is making this more feasible and cost-effective.

5. Meeting ESG goals: Customers, investors, and governments are demanding transparency. Automated systems provide auditable data trails that support ESG reporting and compliance.

In essence, automation enables sustainability not just by doing things faster – but by doing things smarter and cleaner.

Conclusion

The term ‘supply chain’ may soon feel outdated. The linear model – suppliers feeding factories feeding distributors – is being replaced by a dynamic, intelligent, networked system more akin to a neural network than a chain.

Automation is the connective tissue of this transformation. It links data to decisions, machines to humans, and strategy to execution.

From autonomous robots in warehouses to predictive analytics in planning and AI-driven logistics, automation is redefining how goods move, how companies collaborate, and how industries compete.

For plant managers, engineers, and industry professionals, the message is clear: The future of operational excellence lies not just in adopting automation – but in orchestrating it across the full value chain.

The evolution of modern supply chains is far from over. It is, in fact, accelerating toward a world where the most resilient, efficient, and sustainable supply networks are not just automated, but intelligent, adaptive, and alive.

Sustainability & circular supply chains

Sustainability today is no longer a branding exercise – it’s a regulatory and economic imperative. Automation plays a critical role in enabling green, efficient, and circular supply chains.

This is sought to be achieved systematically and methodically, using the tools of technology:

1. Tracking environmental impact: IoT sensors and data platforms track energy usage, emissions, and waste across facilities and transportation networks, helping companies measure and optimise sustainability performance.

2. Reducing waste and inventory: Automation improves demand forecasting, production planning, and inventory control – leading to fewer excess materials and obsolete stock.

3. Optimising routes and loads: AI-based logistics platforms optimise vehicle routes, consolidate loads, and reduce empty miles, lowering fuel consumption and carbon emissions.

4. Reverse logistics and recycling: Circular supply chains require efficient handling of returns, remanufacturing, and recycling. Automation in sorting, inspection, and reverse logistics is making this more feasible and cost-effective.

5. Meeting ESG goals: Customers, investors, and governments are demanding transparency. Automated systems provide auditable data trails that support ESG reporting and compliance.

In essence, automation enables sustainability not just by doing things faster – but by doing things smarter and cleaner.

Conclusion

The term ‘supply chain’ may soon feel outdated. The linear model – suppliers feeding factories feeding distributors – is being replaced by a dynamic, intelligent, networked system more akin to a neural network than a chain.

Automation is the connective tissue of this transformation. It links data to decisions, machines to humans, and strategy to execution.

From autonomous robots in warehouses to predictive analytics in planning and AI-driven logistics, automation is redefining how goods move, how companies collaborate, and how industries compete.

For plant managers, engineers, and industry professionals, the message is clear: The future of operational excellence lies not just in adopting automation – but in orchestrating it across the full value chain.

The evolution of modern supply chains is far from over. It is, in fact, accelerating toward a world where the most resilient, efficient, and sustainable supply networks are not just automated, but intelligent, adaptive, and alive.