Mitsubishi Electric VFDs help farms grow operations

Three-phase power is often unavailable in rural and remote locations, which is a primary reason why farmers struggle to grow their operations. Any farm looking to run larger fans and motors to help increase storage and handling capacity have thus far been forced into using traditional solutions such as rotary phase converters, which are costly, have big capacitor banks and a high amp draw, running up electricity bills and erasing profits. Now, however, increasing numbers are turning to the latest Mitsubishi Electric variable frequency drives (VFDs), which allow a three-phase motor to run from a single-phase electric supply without a phase converter, facilitating greater power and lower energy consumption.

This trend is evidenced by D&E Equipment of Wilmington, Ohio, which was founded in 1954 by Walter Ewing. An expert in designing and installing bespoke farm infrastructure solutions such as grain storage bins, grain elevators, dryers, augers and grain handling systems, D&E is a family-run company that has built a reputation for quality and service throughout the local agricultural community. With no two installations the same, D&E Equipment’s highly experienced workforce collaborates with each customer to fully understand and meet their specific requirements.

The challenge

Modern agricultural operations make use of on-site infrastructure to store and maintain grain, selling their crop in several batches at different prices throughout the year to help maximise returns. Along with farm consolidation, this trend has helped fuel demand for ever-larger grain storage and handling infrastructure. However, since many agricultural operations are located in remote rural areas, they can quickly reach an impasse, severely hampering their ability to grow.

“Unfortunately, many of our customers can only get single-phase power out to their farms,” confirms D&E Vice President of Operations Mike Kees.

With three-phase power vital for running the larger fans, motors and other equipment required to increase storage and handling capacity, farmers seeking operational growth have been forced to use a feasible, if far from desirable workaround: rotary phase converters. However, such devices are not only expensive, but draw large quantities of electricity.

The solution

By working with Mitsubishi Electric and its local distributor, D&E has been able to offer customers a far more attractive solution in the shape of the latest VFDs.

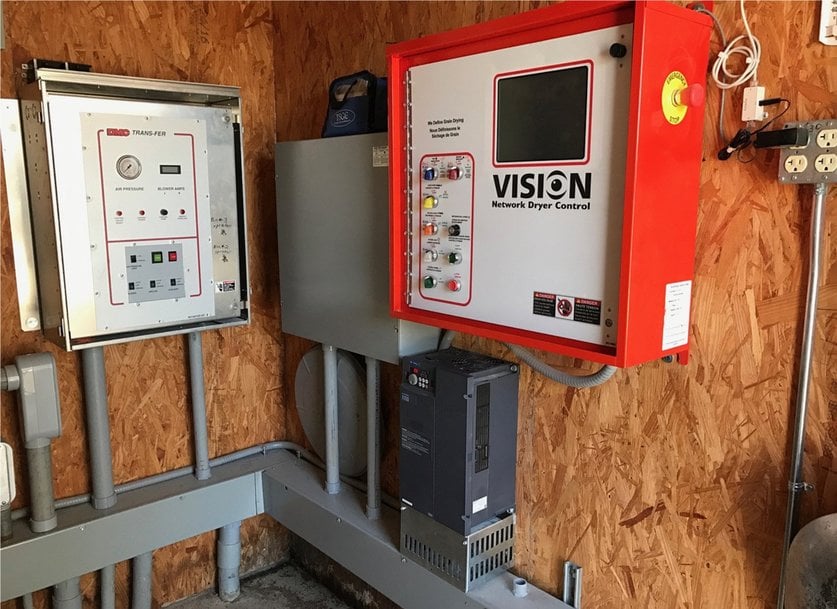

Image2.jpg: A Mitsubishi VFD installed as part of a dryer control system

“Basically Mitsubishi VFDs allow us to ‘trick’ a three-phase motor into running from a single-phase electric supply without a phase converter, enabling greater horsepower,” explains Kees. “And since they are only used on the specific motor or other piece of equipment where they are needed, the VFDs are far more power-efficient and economical to run.”

The impact of a Mitsubishi Electric VFD on a farm’s operation, Kees notes, can be huge – and instantaneous.

“A maximum of 15hp [11.2kW] single-phase power is limiting,” he says. “Installing a Mitsubishi Electric VFD ensures that our customer becomes capable of using larger, faster equipment, while accessing more capacity by increasing the size of their operation. With their single-phase power supply and the VFD, they’re no longer limited on equipment size. A farm can move from, say, 700 bushels per hour to 1200 or 1700 bushels an hour through their drying system by using a conveyor that requires a 30hp (22.4kW) three-phase motor, though they still have a single-phase electricity supply. The VFD provides an immediate opportunity for them to grow their operation in a cost-effective way.”

Image3.jpg: Mitsubishi Electric VFDs can provide a host of problem-solving benefits at farming operations worldwide

According to Kees, this advantage is usually only the beginning as Mitsubishi Electric VFDs potentially provide a host of further problem-solving benefits. Among them is the capability to allow a ‘soft start’ increase of power draw when firing up equipment. This feature reduces the potential for tripping the overload, lowers the possibility of damaging expensive equipment, and increases service life.

Another benefit of VFDs is their ability to simplify the combination of newly purchased equipment with existing older equipment and make it work effectively for the customer, a common challenge on the farm. If one conveyer, for example, is rated at 5000 bushels an hour and another is rated at 7500 bushels an hour, grain plugging and equipment breakage can occur if the incompatibilities are not evened out.

Kees also appreciates how working with Mitsubishi Electric has enabled D&E to create further goodwill with its customers, and maintain and enhance the company’s long-standing reputation for quality: “We are service-driven and stand behind our products, and Mitsubishi helps us in that regard. I don’t think I’ve ever seen one of their VFDs go wrong and require replacement. As a result, with the high costs of service and downtime on the farm, our customers are very happy.”

He also notes that when VFD programming is needed, the customer-focused, partnership-driven attitude of Mitsubishi Electric and its distributor help D&E provide fast, effective service.

“Our prior supplier insisted on keeping their system proprietary; if there was a programming issue we had to call and wait for them to come out,” Kees explains. “It could take several days and support costs were high. Contrast that with the Mitsubishi attitude – they actually train our guys on their system so we can do it ourselves, quickly. Again, that is a huge value add. Mitsubishi has a whole different business model and attitude; a partnership rather than a forced dependency.”

The results

Ultimately, working with Mitsubishi Electric VFDs has created an entirely new stream of business for D&E, and stimulated the company’s interest in potentially helping customers apply additional Mitsubishi Electric automation solutions to grain-handling applications such as those relating to PLC controls, networking and temperature monitoring.

Image4.jpg: Mitsubishi Electric automation solutions can be applied to numerous grain-handling applications

“Mitsubishi VFDs are turning our service guys into sales people because they are going to farms and constantly seeing where customers can benefit,” concludes Kees. “In turn, this elevates job satisfaction among our staff as anytime you can fix something so effectively for a customer you’re going to feel good about it. In my opinion, VFDs will soon become as common on the farm as motors and augers.”

Image5.jpg: Farms can increase storage and handling capacity with Mitsubishi Electric VFDs